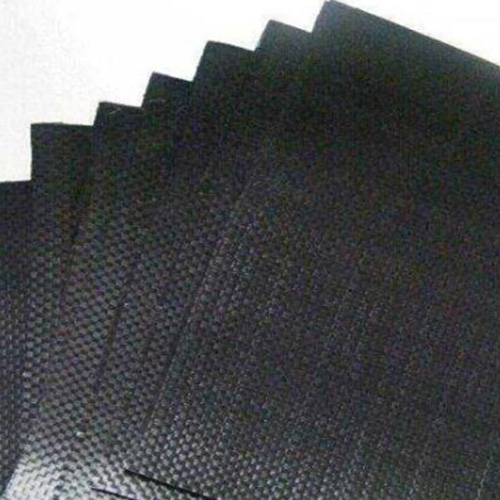

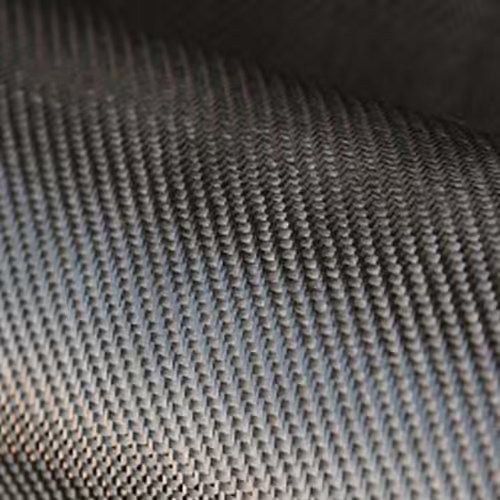

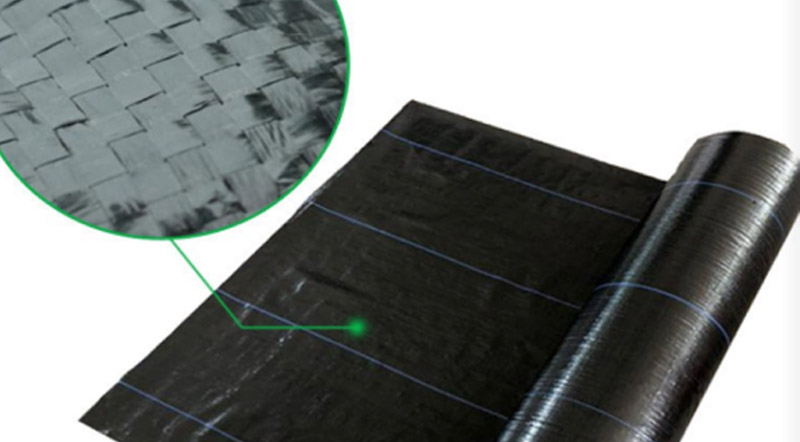

Woven geotextile is made from woven plastic filaments, offering very high tensile strength. It is primarily used for soil reinforcement in civil engineering to enhance stability. Its key function is to separate different soil layers, preventing material mixing. Additionally, its regular pore structure provides excellent drainage.

1. High strength: Woven geotextiles are made of high-strength industrial polypropylene, polyester, nylon and other synthetic fibers as raw materials, and are woven through a regular interwoven structure to further enhance the overall bearing capacity.

2. Durability: The synthetic fiber material of Woven Geotextile is stable and not easy to degenerate, decompose or weather, ensuring that the original characteristics are maintained for a long time.

3. Corrosion resistance: Woven Geotextile are usually acid-resistant, alkali-resistant, insect-resistant and mold-resistant, and can adapt to various complex environments.

4. Water permeability: The structural pores of Woven Geotextile are controllable, providing a certain degree of water permeability to meet engineering needs.

5. Convenient storage and transportation: Woven Geotextile are lightweight and can be packaged on demand, and the transportation, storage and construction processes are simple and efficient.

Parámetros del producto

| Modelo NO. | Woven geotextile | Color | Personalizable |

| Certification | CE ISO | Feature | High strength, low elongation, drainage |

| Material | pp/pet/pe | Amable | woven |

| Width | 1m-6m (as Customrized) | Length | 100-600m or Customized |

| Weight | 70-800GSM(as Customrized) | Standard | ASTM or customer requirements |

| Geotextile Type | Woven Geotextiles | Paquete de transporte | Inner Pipe + Outside Woven Bag or Film |

| Origen | China | Marca | EcoGeo |

Product Feature

1.High strength: Due to its woven structure, it has high tensile strength and modulus in both the warp and weft directions (i.e., it is not easily stretched), enabling it to withstand enormous loads.

2.Excellent mechanical properties: stable structure, effective load distribution, and reduced uneven settlement.

3.Uniform porosity: Its pores are regular and continuous, and their main function is drainage and water conduction, rather than backfiltering (preventing soil erosion).

4.Durability: Resistant to chemical corrosion, insect damage, and ageing, with a longer service life.

4.Durability: Resistant to chemical corrosion, insect damage, and ageing, with a longer service life.

Product Details

Durability: Resistant to chemical corrosion, insect damage, and ageing, with a long service life.

Good mechanical properties

Uniform porosity

Application Scenarios

Transport infrastructure such as roads, railways and airports

Water engineering (dams, riverbanks, sea walls)

Environmental protection projects (landfills, mine tailings ponds)

Other applications (geotextile bags/geotextile Geotextile Tubes, agriculture and aquaculture)

Landscaping & Agriculture:For soil stabilization, drainage, and weed control.

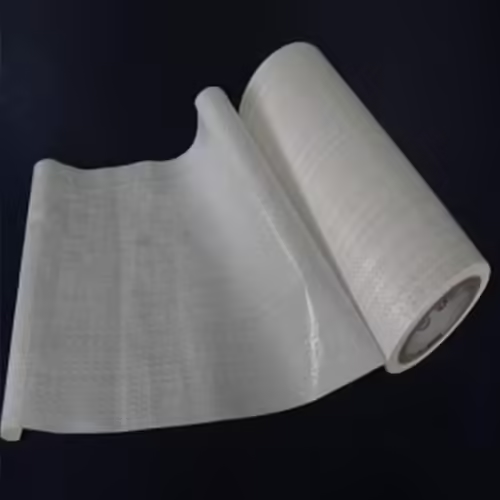

Packaging and delivery

Packaging unit: Rolled (width and length of each roll can be customized according to customer requirements)

Packaging method: plastic film, plastic woven bags, or packaging designed by the customer.

Packaging method: plastic film, plastic woven bags, or packaging designed by the customer.

Preguntas frecuentes

How do I choose the right woven geotextile for my project?

It is essential to adhere to the technical specifications provided by the engineering designer. Do not make selections based solely on personal preference or price. The designer will calculate the minimum strength requirements based on the purpose of the project (reinforcement or separation), load size, foundation conditions, and other factors.

How can you easily determine the quality of woven geotextiles?

Can woven geotextiles be spliced? How are they spliced?

Productos relacionados

Nos centramos en

protección ambiental

Concepto de protección del medio ambiente para crear un futuro verde

Estamos comprometidos con la protección del medio ambiente, y una forma de lograr un desarrollo sostenible en la industria de los geosintéticos es utilizar materiales reciclables o renovables en el proceso de producción. Esto puede reducir la dependencia de recursos limitados, contribuir al ahorro energético y reducir las emisiones de gases de efecto invernadero. Además, las empresas pueden implementar procesos de producción eficientes para minimizar los residuos y optimizar el uso de los recursos.

Las ventajas de nuestros productos

Alto rendimiento y confiabilidad

Todos nuestros productos están diseñados para brindar resistencia mecánica superior, resistencia química y durabilidad a largo plazo, lo que garantiza un rendimiento constante incluso en las condiciones ambientales y estructurales más exigentes.

Soluciones rentables y eficientes

Gracias a la fabricación avanzada y la optimización de materiales, nuestros productos ofrecen un valor excepcional al reducir el tiempo de instalación, minimizar el mantenimiento y extender la vida útil de los sistemas de infraestructura.

Diseño ambientalmente responsable

Priorizamos la sostenibilidad utilizando materiales reciclables, reduciendo los residuos de construcción y apoyando prácticas de ingeniería ecológicas que se alineen con los estándares ambientales globales.

Preguntas frecuentes

¿Quienes somos?

¿A qué mercados han llegado nuestros productos?

¿Cómo garantizamos la calidad del producto?

¿Cuál es la vida útil de la geomembrana?

¿Cuáles son las especificaciones de las geomembranas?

¿Nuestras geomembranas son adecuadas para entornos especiales?

¿Qué condiciones de entrega y métodos de pago ofrecemos?

¿Podemos proporcionar muestras?

Contáctenos

Construyamos algo más fuerte, más inteligente y más ecológico