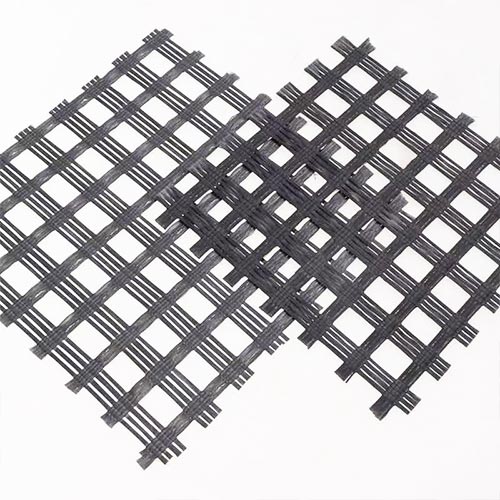

1. Fiberglass Geogrid is an excellent geosynthetic material used for road reinforcement, old road strengthening, and the consolidation of subgrades, including soft soil subgrades.

2. Fiberglass Geogrid has become an irreplaceable material in the treatment of reflective cracks in asphalt pavements.

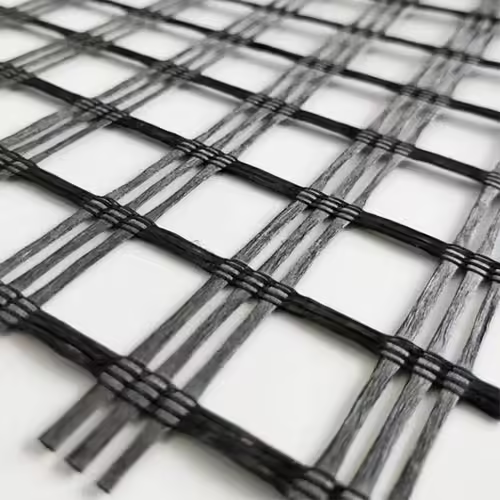

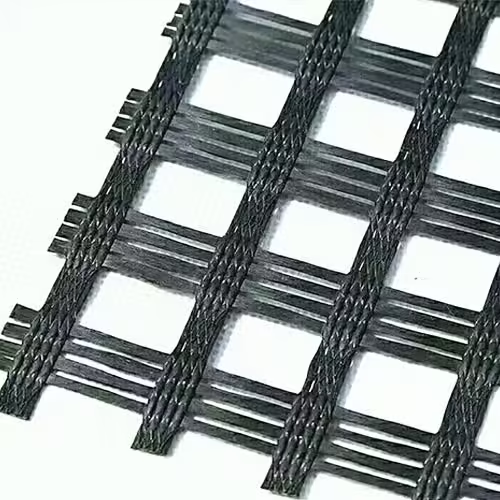

3. Fiberglass Geogrid is made from GQ alkali-free glass fiber, which is processed into a mesh base material through advanced international warp-knitting technology and then treated with surface coating to produce a semi-rigid product.

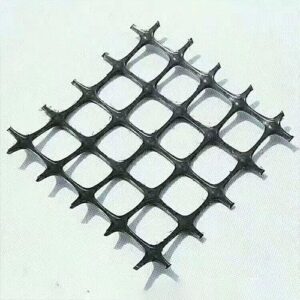

4. Fiberglass Geogrid features high tensile strength in both warp and weft directions, low elongation rate, and excellent properties such as high-temperature resistance, low-temperature resistance, aging resistance, and corrosion resistance.

5. Fiberglass Geogrid is widely used in the reinforcement of asphalt and cement pavements, as well as in railway subgrades, embankment slopes, airport runways, and sand control and desertification prevention projects.

Parámetros del producto

| Modelo NO. | Fiberglass Geogrid | Color | Black |

| Application | Retaining Wall, Steep Slop, Dam, Road Base | Viscose | Without Viscose |

| Function | Anti-slip, Reinforcement | Classification | Geomalla de plástico |

| Material | Plastic | Length | 50m-100m |

| Width | 1m-6m | Certificate | CE/ISO9001 |

| Resistencia a la tracción | 15kn/M–300kn/M | Elongation at Break | 13% Max |

| Capacidad de producción | 50000 Square Maters/ Day | Sample | Freely |

| Model Number | 25kn/M–300kn/M | Mesh Size (mm) | 12.7*12.7mm. 25.4*25.4mm |

| Package | PP Woven Bags | Coating | Bitumen,PVC |

| Usage | Road Construction | Breaking Elongation | 4% |

| Advantage | High Strength /Long Life Service | Paquete de transporte | PP Plastic Geogrid Is Usually Packed by PP Woven B |

| Especificación | 5.8m*100m | Marca | EcoGeo |

| Origen | Shandong | Código HS | 3926909090 |

Advantages

Fiberglass Geogrid is an excellent geosynthetic material used for road reinforcement, old road strengthening, and the consolidation of subgrades, including soft soil subgrades.

Fiberglass Geogrid has become an irreplaceable material in the treatment of reflective cracks in asphalt pavements.

Fiberglass Geogrid is made from GQ alkali-free glass fiber, which is processed into a mesh base material through advanced international warp-knitting technology and then treated with surface coating to produce a semi-rigid product.

Fiberglass Geogrid features high tensile strength in both warp and weft directions, low elongation rate, and excellent properties such as high-temperature resistance, low-temperature resistance, aging resistance, and corrosion resistance.

5. Fiberglass Geogrid is widely used in the reinforcement of asphalt and cement pavements, as well as in railway subgrades, embankment slopes, airport runways, and sand control and desertification prevention projects.

Adopts GQ alkali-free glass fibers, processed into mesh base material via internationally advanced warp knitting technology, then surface-coated to form a semi-rigid product.

Boasts high tensile strength in both warp and weft directions, low elongation, and excellent resistance to high/low temperatures, aging, and corrosion.

An irreplaceable material for road reinforcement, old road renovation, subgrade consolidation (including soft soil subgrades), and treating asphalt pavement reflective cracks.

Fiberglass Geogrid has become an irreplaceable material in the treatment of reflective cracks in asphalt pavements.

Fiberglass Geogrid is made from GQ alkali-free glass fiber, which is processed into a mesh base material through advanced international warp-knitting technology and then treated with surface coating to produce a semi-rigid product.

Fiberglass Geogrid features high tensile strength in both warp and weft directions, low elongation rate, and excellent properties such as high-temperature resistance, low-temperature resistance, aging resistance, and corrosion resistance.

5. Fiberglass Geogrid is widely used in the reinforcement of asphalt and cement pavements, as well as in railway subgrades, embankment slopes, airport runways, and sand control and desertification prevention projects.

Adopts GQ alkali-free glass fibers, processed into mesh base material via internationally advanced warp knitting technology, then surface-coated to form a semi-rigid product.

Boasts high tensile strength in both warp and weft directions, low elongation, and excellent resistance to high/low temperatures, aging, and corrosion.

An irreplaceable material for road reinforcement, old road renovation, subgrade consolidation (including soft soil subgrades), and treating asphalt pavement reflective cracks.

Product application scenarios

Fiberglass geogrids are widely used in the field of infrastructure. In road engineering, they can reinforce asphalt or cement pavements, reduce rutting and cracking. They are also applicable to the renovation of old roads and the treatment of soft soil subgrades, thereby improving subgrade stability. In railway construction, they can enhance the bearing capacity of track subgrades and alleviate settlement.

In the construction of airport runways, they help improve the integrity of the foundation to cope with the impact of frequent take-offs and landings. Moreover, they play an important role in mine reclamation, sand control projects, and foundation treatment of large stadiums. By interlocking with soil to disperse loads, they reduce construction costs and extend the service life of projects.

In the construction of airport runways, they help improve the integrity of the foundation to cope with the impact of frequent take-offs and landings. Moreover, they play an important role in mine reclamation, sand control projects, and foundation treatment of large stadiums. By interlocking with soil to disperse loads, they reduce construction costs and extend the service life of projects.

Factory and packaging pictures:

Productos relacionados

Nos centramos en

protección ambiental

Concepto de protección del medio ambiente para crear un futuro verde

Estamos comprometidos con la protección del medio ambiente, y una forma de lograr un desarrollo sostenible en la industria de los geosintéticos es utilizar materiales reciclables o renovables en el proceso de producción. Esto puede reducir la dependencia de recursos limitados, contribuir al ahorro energético y reducir las emisiones de gases de efecto invernadero. Además, las empresas pueden implementar procesos de producción eficientes para minimizar los residuos y optimizar el uso de los recursos.

Las ventajas de nuestros productos

Alto rendimiento y confiabilidad

Todos nuestros productos están diseñados para brindar resistencia mecánica superior, resistencia química y durabilidad a largo plazo, lo que garantiza un rendimiento constante incluso en las condiciones ambientales y estructurales más exigentes.

Soluciones rentables y eficientes

Gracias a la fabricación avanzada y la optimización de materiales, nuestros productos ofrecen un valor excepcional al reducir el tiempo de instalación, minimizar el mantenimiento y extender la vida útil de los sistemas de infraestructura.

Diseño ambientalmente responsable

Priorizamos la sostenibilidad utilizando materiales reciclables, reduciendo los residuos de construcción y apoyando prácticas de ingeniería ecológicas que se alineen con los estándares ambientales globales.

Preguntas frecuentes

¿Quienes somos?

¿A qué mercados han llegado nuestros productos?

¿Cómo garantizamos la calidad del producto?

¿Cuál es la vida útil de la geomembrana?

¿Cuáles son las especificaciones de las geomembranas?

¿Nuestras geomembranas son adecuadas para entornos especiales?

¿Qué condiciones de entrega y métodos de pago ofrecemos?

¿Podemos proporcionar muestras?

Contáctenos

Construyamos algo más fuerte, más inteligente y más ecológico