Índice

Introdução

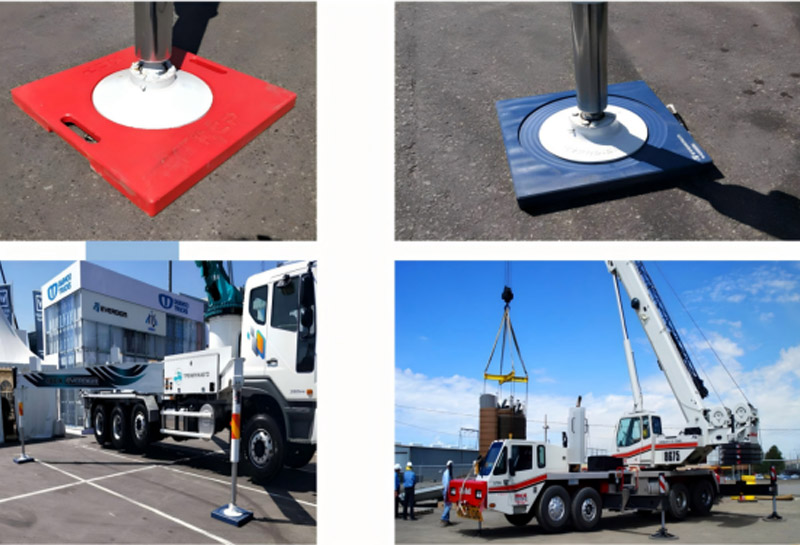

When managing construction sites, ensuring the safety and stability of heavy machinery is paramount. Crane outrigger pads are an often-overlooked yet critical component during construction. These pads are essential for distributing the weight of cranes and other heavy equipment, particularly when operating on soft or uneven ground.

EcoGeo Material, a leading geosynthetic manufacturer headquartered in Shandong, China, specializes in producing durable, high-performance outrigger pads designed for construction, environmental, and infrastructure projects. In this blog, we explore the critical role of these pads, their advantages, and why they are vital for construction site safety.

Why Crane Outrigger Pads Are Crucial for Construction Site Safety

Crane outrigger pads are designed to ensure that the weight of the crane and its load is evenly distributed across the ground. Without these pads, the crane would exert too much pressure on the surface below, increasing the risk of soil damage, tip-overs, or equipment failure. Properly installed outrigger pads help prevent ground penetration, which can cause instability and unsafe working conditions.

On construction sites where heavy lifting and precision are required, outrigger pads act as the primary tool for stabilizing cranes during operations. Whether the crane is lifting heavy materials, moving across uneven terrain, or operating in high-risk environments, these pads absorb the pressure, ensuring the stability of both the crane and the site.

How Crane Outrigger Pads Prevent Crane Tip-Over

Crane tip-overs are one of the most dangerous incidents on construction sites, often resulting in damage, injury, or loss of life. Crane outrigger pads significantly reduce the risk of such accidents. By distributing the crane’s weight over a larger area, they prevent the equipment from sinking into soft soil, which could lead to the crane tipping over.

The larger the outrigger pad, the more weight it can handle, ensuring the crane stays balanced even when lifting heavy or off-center loads. Whether working on a compact urban site or an expansive construction zone, having the correct size and type of outrigger pad is critical for ensuring that the crane’s stabilizers remain effective.

Choosing the Right Crane Outrigger Pads for Different Terrain Types

The performance of outrigger pads is closely tied to the type of terrain on which they are placed. Soft or unstable surfaces, such as clay, sand, or even gravel, require pads with higher load-bearing capacities and larger surface areas. In contrast, stable, hard ground may need smaller, more compact pads.

Material selection also plays a role. Crane outrigger pads are made from various materials, including plastic composites, timber, and metal, each suited to different working conditions. Choosing the right material is crucial to ensure that the pad can withstand the weight of the crane and the environmental factors it may face on the job site.

Table: Different Types of Crane Outrigger Pads and Their Applications

| Tipo de material | Ideal Use | Key Features |

|---|---|---|

| Plastic Composites | Construction, Urban Sites | Lightweight, corrosion-resistant, durable |

| Timber | Soft Ground, Landscaping | Cost-effective, flexible, eco-friendly |

| Metal | Heavy Lifting, Rough Terrain | High strength, excellent load-bearing capacity |

| Rubber | Sensitive Areas, Short-Term Use | Non-marring, vibration dampening, easy to handle |

The Benefits of Using Crane Outrigger Pads in Heavy Lifting Operations

In heavy lifting operations, especially in high-stakes construction environments, the crane outrigger pads are indispensable. Their primary function is to provide a safe and stable foundation for cranes, ensuring that they can lift and move materials without the risk of the crane becoming unbalanced.

For lifting operations involving large or unevenly distributed loads, it’s important to use high-quality outrigger pads. These pads distribute the load across a wider area, preventing excessive stress on any single point, which can lead to structural failure or equipment malfunction.

How Outrigger Pads Help Meet Safety Regulations

Many construction sites are governed by strict safety regulations that require the proper use of crane outrigger pads. Compliance with these regulations is essential to avoid legal and financial consequences, as well as to protect workers on the ground.

Crane outrigger pads are often part of a broader safety strategy designed to prevent accidents and enhance site stability. In some jurisdictions, outrigger pads are required by law to ensure that heavy machinery does not pose a risk to the surrounding environment or personnel. Regular maintenance and inspection of the pads are essential to maintain safety standards and ensure optimal performance.

Crane Outrigger Pads and Their Role in Reducing Environmental Impact

Almofadas de estabilizador

Vantagens

Easy to install and replace

Reduce downtime

Lower maintenance costs

Non-stick surface, easy to clean

Operate at subzero temperatures.

Corrosion-resistant, chemical-resistant, wear-resistant, and moisture-proof

High load-carrying capacity

On construction sites, especially those near sensitive environments like wetlands, forests, or agricultural areas, the environmental impact of heavy machinery must be carefully considered. Using outrigger pads reduces the environmental damage that cranes might cause by spreading the load over a larger surface area. This prevents soil compaction, minimizes the risk of erosion, and protects vegetation from heavy equipment damage.

By using high-quality outrigger pads, construction companies can ensure they are not only improving site safety but also minimizing their ecological footprint. This is increasingly important as environmental regulations become more stringent across industries.

Conclusão

Crane outrigger pads are more than just equipment—they are essential for ensuring safety and stability on construction sites. Whether you’re working on a small residential project or a large industrial site, using the right outrigger pads helps prevent accidents, reduce environmental impact, and enhance overall site safety.

Material EcoGeo specializes in providing high-quality crane outrigger pads designed for both durability and performance. Whether you’re lifting heavy loads or operating on soft ground, our pads meet your project demands. Don’t wait for an accident to happen—entre em contato conosco hoje to select the right crane outrigger pads and ensure your construction site remains safe and compliant.

Perguntas frequentes

How do I know if I need sapatas estabilizadoras de guindaste?

If your crane is operating on soft or uneven ground, outrigger pads are a must. They help distribute the weight of the crane and prevent instability, which is critical to the safety of the operation.

How often should I inspect my outrigger pads?

Regular inspections are essential. Check the pads for any signs of wear or damage before every major lift. A damaged outrigger pad can compromise safety, so replace it immediately if needed.

Can crane outrigger pads be reused?

Yes, outrigger pads can often be reused, provided they are in good condition. Always inspect them for cracks, warping, or other damage before reuse.

Do crane outrigger pads come in different sizes?

Yes, outrigger pads come in various sizes to accommodate different types of cranes and site conditions. Be sure to choose the right size based on the crane’s weight and the surface area of the site.