Outrigger Pads are mainly used to be placed under the legs of construction machinery, serving as a support function. These pads have high strength and stiffness, which enables them to reduce the deformation of the pad body during force application, thereby providing a more stable supporting force for the construction

Product Parameters

| Country of Origin | Shandong, China |

| Model | Crane Pad |

| Material | UHMWPE |

| Thickness | Customizable,

Common Thicknesses: 50mm,60mm,80mm,150mm,100mm |

| Size | Customizable |

| Material | Composite Material UHMWPE (ultra-high molecular weight polyethylene) |

| Product Name | Heavy Duty Outrigger Jack Pads |

| Color | Black, yellow, Res, etc. |

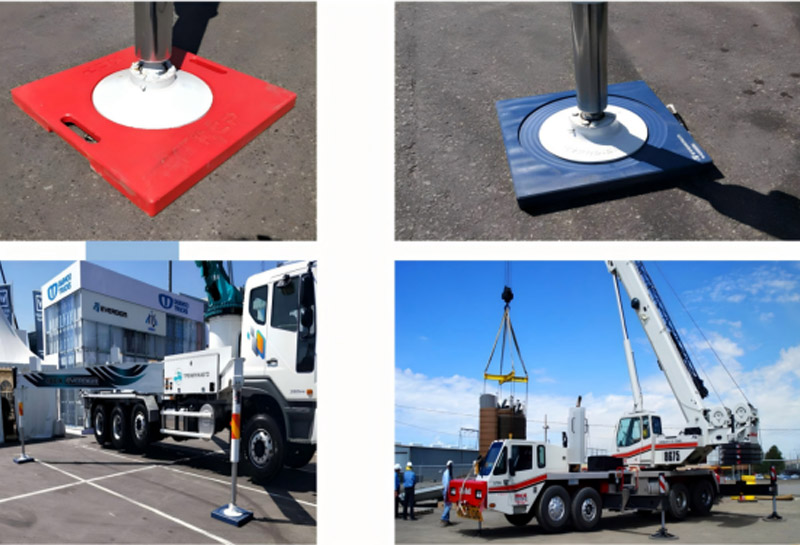

| App | Crane trucks, heavy vehicles, RVs, fire trucks, aerial work platforms |

| Capacity | As Your Custom |

| Serve | OEM\ODM |

| Keywords | Building Blocks, Stabilizing Pads |

| Function | Environmental Friendly |

| Density | 0.96-0.97 |

| Surface finish | Custom Surface Textures |

| Country of Origin | Shandong, China |

Advantages

Easy to install and replace

Reduce downtime

Lower maintenance costs

Non - stick surface, easy to clean

Operate at sub - zero temperatures

Corrosion - resistant, chemical - resistant, wear - resistant and moisture - proof

High load - carrying capacity

Reduce downtime

Lower maintenance costs

Non - stick surface, easy to clean

Operate at sub - zero temperatures

Corrosion - resistant, chemical - resistant, wear - resistant and moisture - proof

High load - carrying capacity

Detailed picture

A portable handle can be added for easier use.

Non-slip surface texture for safer use

Non-slip surface texture for safer use

Workshop Map

Application Diagram

Its main function is to be placed under the outriggers of construction machinery such as cranes or pump trucks. By increasing the ground contact area, it disperses the huge pressure and effectively prevents the vehicle from sinking when operating on soft ground.

The material properties of high strength and corrosion resistance ensure that the backing plate can withstand heavy loads and harsh environments for a long time, thus guaranteeing the safety and stability during the construction process.

The material properties of high strength and corrosion resistance ensure that the backing plate can withstand heavy loads and harsh environments for a long time, thus guaranteeing the safety and stability during the construction process.

Packaging

Perguntas frequentes

What material are your outrigger pads made of?

We mainly offer high-strength HDPE (High-Density Polyethylene) and UHMW-PE (Ultra-High Molecular Weight Polyethylene) materials. Both materials are highly wear-resistant, corrosion-resistant, and have strong load-bearing capacity.

What is the maximum load capacity?

What options are available for size and thickness?

Why is the surface designed with grid patterns or anti-slip textures?

Are they suitable for use on soft ground (such as muddy ground, sandy ground)?

How is the weather resistance?

What is the price? Are there any discounts?

Do you have quality certifications?

Can you provide OEM/customization services?

What are the payment methods and delivery time?

What is the minimum order quantity (MOQ)?

Related products

We focus on

environmental protection

Environmental protection concept to create a green future

We are committed to the field of environmental protection, and one way to achieve sustainable development in the geosynthetics industry is to use recyclable or renewable materials in the production process. This can reduce dependence on limited resources and help conserve energy and reduce greenhouse gas emissions. Additionally, companies can implement efficient production processes to minimize waste and optimize resource utilization.

Our product advantages

High Performance and Reliability

All our products are engineered for superior mechanical strength, chemical resistance, and long-term durability—ensuring consistent performance even in the most demanding environmental and structural conditions.

Cost-Effective and Efficient Solutions

Through advanced manufacturing and material optimization, our products deliver exceptional value by reducing installation time, minimizing maintenance, and extending the lifespan of infrastructure systems.

Environmentally Responsible Design

We prioritize sustainability by using recyclable materials, reducing construction waste, and supporting eco-friendly engineering practices that align with global environmental standards.

Perguntas frequentes

Who are we?

Which markets have our products reached?

How do we ensure product quality?

What is the lifespan of the geomembrane?

What are the specifications of the geomembranes?

Are our geomembranes suitable for special environments?

What delivery terms and payment methods do we offer?

Can we provide samples?

Contate-nos

Let’s Build Something Stronger, Smarter, and Greener