1. Fiberglass Geogrid is an excellent geosynthetic material used for road reinforcement, old road strengthening, and the consolidation of subgrades, including soft soil subgrades.

2. Fiberglass Geogrid has become an irreplaceable material in the treatment of reflective cracks in asphalt pavements.

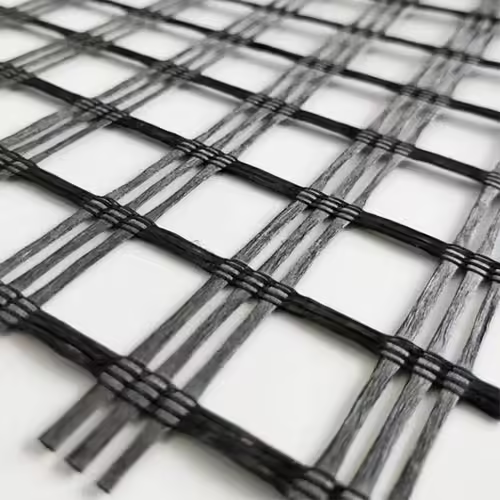

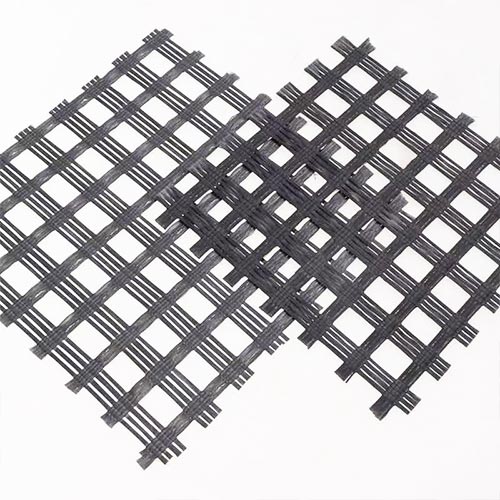

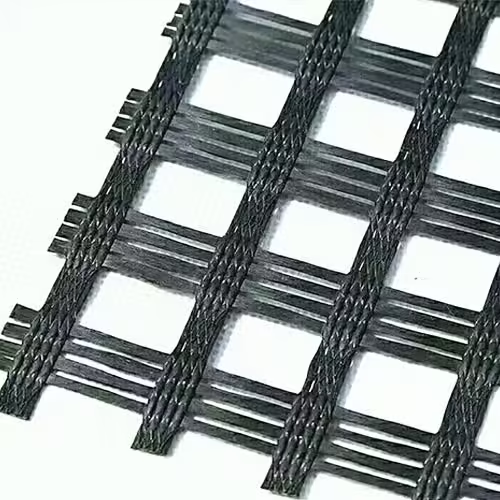

3. Fiberglass Geogrid is made from GQ alkali-free glass fiber, which is processed into a mesh base material through advanced international warp-knitting technology and then treated with surface coating to produce a semi-rigid product.

4. Fiberglass Geogrid features high tensile strength in both warp and weft directions, low elongation rate, and excellent properties such as high-temperature resistance, low-temperature resistance, aging resistance, and corrosion resistance.

5. Fiberglass Geogrid is widely used in the reinforcement of asphalt and cement pavements, as well as in railway subgrades, embankment slopes, airport runways, and sand control and desertification prevention projects.

Product Parameters

| Model NO. | Fiberglass Geogrid | Color | Black |

| Application | Retaining Wall, Steep Slop, Dam, Road Base | Viscose | Without Viscose |

| Function | Anti-slip, Reinforcement | Classification | Geogrelha de plástico |

| Material | Plastic | Length | 50m-100m |

| Width | 1m-6m | Certificate | CE/ISO9001 |

| Tensile Strength | 15kn/M–300kn/M | Elongation at Break | 13% Max |

| Capacidade de produção | 50000 Square Maters/ Day | Sample | Freely |

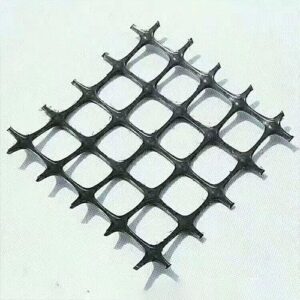

| Model Number | 25kn/M–300kn/M | Mesh Size (mm) | 12.7*12.7mm. 25.4*25.4mm |

| Package | PP Woven Bags | Coating | Bitumen,PVC |

| Usage | Road Construction | Breaking Elongation | 4% |

| Advantage | High Strength /Long Life Service | Transport Package | PP Plastic Geogrid Is Usually Packed by PP Woven B |

| Specification | 5.8m*100m | Trademark | EcoGeo |

| Origin | Shandong | HS Code | 3926909090 |

Advantages

Fiberglass Geogrid is an excellent geosynthetic material used for road reinforcement, old road strengthening, and the consolidation of subgrades, including soft soil subgrades.

Fiberglass Geogrid has become an irreplaceable material in the treatment of reflective cracks in asphalt pavements.

Fiberglass Geogrid is made from GQ alkali-free glass fiber, which is processed into a mesh base material through advanced international warp-knitting technology and then treated with surface coating to produce a semi-rigid product.

Fiberglass Geogrid features high tensile strength in both warp and weft directions, low elongation rate, and excellent properties such as high-temperature resistance, low-temperature resistance, aging resistance, and corrosion resistance.

5. Fiberglass Geogrid is widely used in the reinforcement of asphalt and cement pavements, as well as in railway subgrades, embankment slopes, airport runways, and sand control and desertification prevention projects.

Adopts GQ alkali-free glass fibers, processed into mesh base material via internationally advanced warp knitting technology, then surface-coated to form a semi-rigid product.

Boasts high tensile strength in both warp and weft directions, low elongation, and excellent resistance to high/low temperatures, aging, and corrosion.

An irreplaceable material for road reinforcement, old road renovation, subgrade consolidation (including soft soil subgrades), and treating asphalt pavement reflective cracks.

Fiberglass Geogrid has become an irreplaceable material in the treatment of reflective cracks in asphalt pavements.

Fiberglass Geogrid is made from GQ alkali-free glass fiber, which is processed into a mesh base material through advanced international warp-knitting technology and then treated with surface coating to produce a semi-rigid product.

Fiberglass Geogrid features high tensile strength in both warp and weft directions, low elongation rate, and excellent properties such as high-temperature resistance, low-temperature resistance, aging resistance, and corrosion resistance.

5. Fiberglass Geogrid is widely used in the reinforcement of asphalt and cement pavements, as well as in railway subgrades, embankment slopes, airport runways, and sand control and desertification prevention projects.

Adopts GQ alkali-free glass fibers, processed into mesh base material via internationally advanced warp knitting technology, then surface-coated to form a semi-rigid product.

Boasts high tensile strength in both warp and weft directions, low elongation, and excellent resistance to high/low temperatures, aging, and corrosion.

An irreplaceable material for road reinforcement, old road renovation, subgrade consolidation (including soft soil subgrades), and treating asphalt pavement reflective cracks.

Product application scenarios

Fiberglass geogrids are widely used in the field of infrastructure. In road engineering, they can reinforce asphalt or cement pavements, reduce rutting and cracking. They are also applicable to the renovation of old roads and the treatment of soft soil subgrades, thereby improving subgrade stability. In railway construction, they can enhance the bearing capacity of track subgrades and alleviate settlement.

In the construction of airport runways, they help improve the integrity of the foundation to cope with the impact of frequent take-offs and landings. Moreover, they play an important role in mine reclamation, sand control projects, and foundation treatment of large stadiums. By interlocking with soil to disperse loads, they reduce construction costs and extend the service life of projects.

In the construction of airport runways, they help improve the integrity of the foundation to cope with the impact of frequent take-offs and landings. Moreover, they play an important role in mine reclamation, sand control projects, and foundation treatment of large stadiums. By interlocking with soil to disperse loads, they reduce construction costs and extend the service life of projects.

Factory and packaging pictures:

Related products

We focus on

environmental protection

Environmental protection concept to create a green future

We are committed to the field of environmental protection, and one way to achieve sustainable development in the geosynthetics industry is to use recyclable or renewable materials in the production process. This can reduce dependence on limited resources and help conserve energy and reduce greenhouse gas emissions. Additionally, companies can implement efficient production processes to minimize waste and optimize resource utilization.

Our product advantages

High Performance and Reliability

All our products are engineered for superior mechanical strength, chemical resistance, and long-term durability—ensuring consistent performance even in the most demanding environmental and structural conditions.

Cost-Effective and Efficient Solutions

Through advanced manufacturing and material optimization, our products deliver exceptional value by reducing installation time, minimizing maintenance, and extending the lifespan of infrastructure systems.

Environmentally Responsible Design

We prioritize sustainability by using recyclable materials, reducing construction waste, and supporting eco-friendly engineering practices that align with global environmental standards.

Perguntas frequentes

Who are we?

Which markets have our products reached?

How do we ensure product quality?

What is the lifespan of the geomembrane?

What are the specifications of the geomembranes?

Are our geomembranes suitable for special environments?

What delivery terms and payment methods do we offer?

Can we provide samples?

Contate-nos

Let’s Build Something Stronger, Smarter, and Greener