Ultra-High-Molecular-Weight Polyethylene Liners(also known as UHMW-PE liners), due to its excellent self-lubricating property and non-stickiness, ensures that its surface does not adhere to fine particles. This characteristic of Ultra-high molecular liner is particularly prominent in the application of linings for bulk material storage and transportation equipment.

Product Parameters

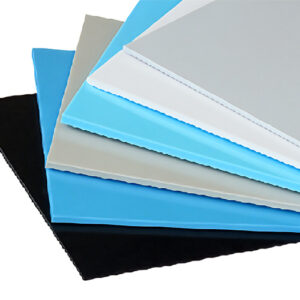

| Material | PE |

| Thickness | 10-200 mm |

| Size | Customized |

| Material | Ultra High Molecular Weight Polyethylene |

| Color | Red/Black/Blue/Yellow/Green/White/Customized |

| Surface | High Surface Hardness |

| Feature | Durable |

| Density | 0.93-0.97g/cm3 |

| Wear Rate: | 0.3~0.45 |

| UHMWPE Molecular Weight | 3 million – 8 million |

| Water Absorption | <0.01 |

| Certificate | ISO/CE |

| Application | Chemical Equipment, Mechanical Parts, Food Processing, Mine, etc. |

Advantages

High wear resistance and abrasion resistance;

Excellent low-temperature impact resistance;

Good self-lubricating performance and no surface adhesion;

Unbreakable, good elasticity, and super strong anti-aging ability;

Odorless and non-toxic; Extremely low hygroscopicity;

Very low friction coefficient;

Highly resistant to corrosive chemicals except oxidizing acids

Excellent low-temperature impact resistance;

Good self-lubricating performance and no surface adhesion;

Unbreakable, good elasticity, and super strong anti-aging ability;

Odorless and non-toxic; Extremely low hygroscopicity;

Very low friction coefficient;

Highly resistant to corrosive chemicals except oxidizing acids

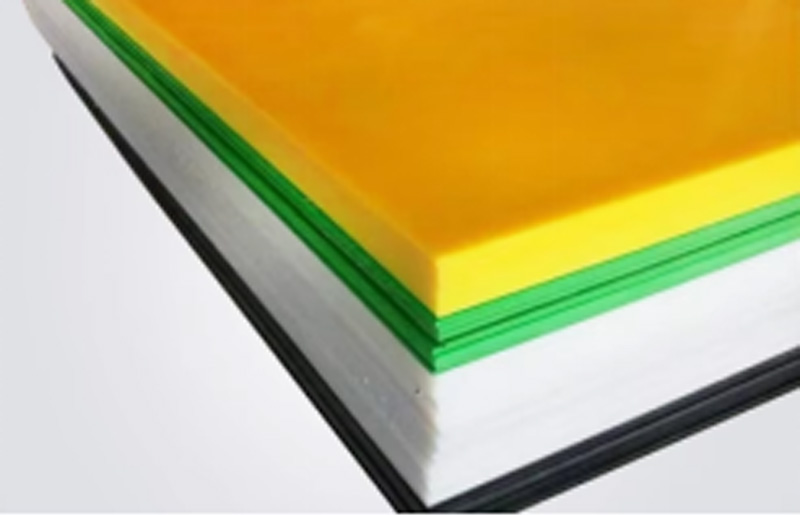

Detailed picture

It features excellent properties such as super wear resistance, self-lubrication, high strength, stable chemical performance, and strong anti-aging performance.

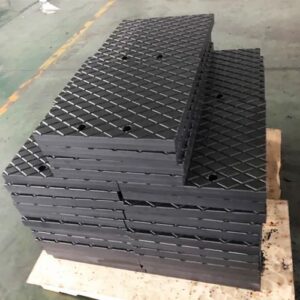

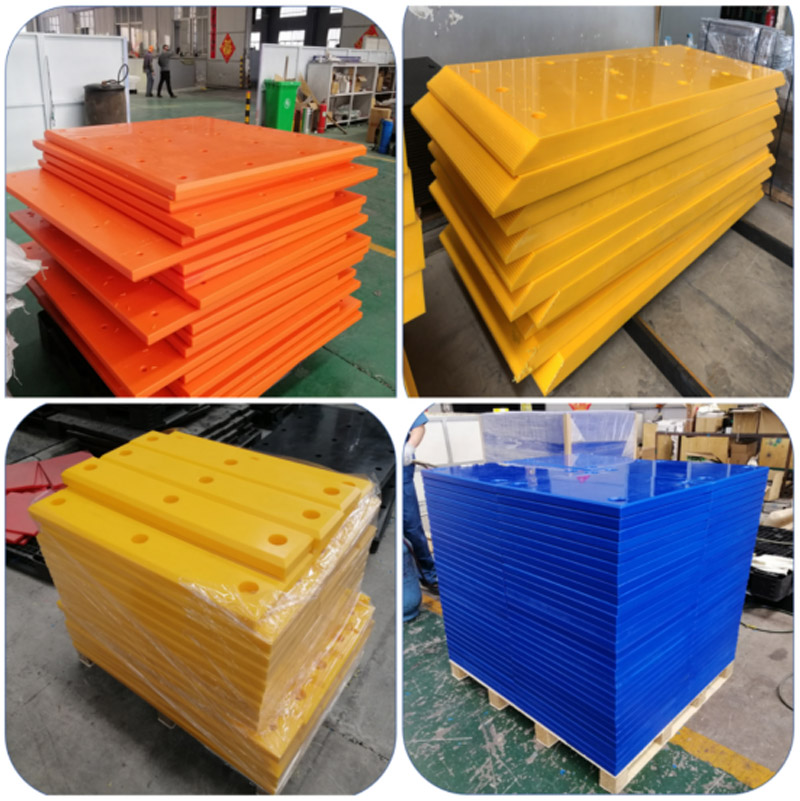

Workshop Map

Application Diagram

It is installed as a lining on the inner walls of hoppers of equipment such as forklifts and dump trucks. By virtue of its extremely low friction coefficient and excellent wear resistance, it prevents sticky materials (such as soil and coal) from adhering and accumulating.

It has significantly reduced the unloading resistance and hopper wear. It not only protects the metal body of the equipment and extends its service life but also effectively improves loading and unloading efficiency and operational economy.

It has significantly reduced the unloading resistance and hopper wear. It not only protects the metal body of the equipment and extends its service life but also effectively improves loading and unloading efficiency and operational economy.

Packaging

Perguntas frequentes

What material is this?

It is mainly ultra-high molecular weight polyethylene (UHMW-PE), which offers extremely high wear resistance and impact resistance.

Where is it mainly used?

What advantages does it have compared to steel plates?

How to install it?

Is it resistant to low temperatures?

Related products

We focus on

environmental protection

Environmental protection concept to create a green future

We are committed to the field of environmental protection, and one way to achieve sustainable development in the geosynthetics industry is to use recyclable or renewable materials in the production process. This can reduce dependence on limited resources and help conserve energy and reduce greenhouse gas emissions. Additionally, companies can implement efficient production processes to minimize waste and optimize resource utilization.

Our product advantages

High Performance and Reliability

All our products are engineered for superior mechanical strength, chemical resistance, and long-term durability—ensuring consistent performance even in the most demanding environmental and structural conditions.

Cost-Effective and Efficient Solutions

Through advanced manufacturing and material optimization, our products deliver exceptional value by reducing installation time, minimizing maintenance, and extending the lifespan of infrastructure systems.

Environmentally Responsible Design

We prioritize sustainability by using recyclable materials, reducing construction waste, and supporting eco-friendly engineering practices that align with global environmental standards.

Perguntas frequentes

Who are we?

Which markets have our products reached?

How do we ensure product quality?

What is the lifespan of the geomembrane?

What are the specifications of the geomembranes?

Are our geomembranes suitable for special environments?

What delivery terms and payment methods do we offer?

Can we provide samples?

Contate-nos

Let’s Build Something Stronger, Smarter, and Greener