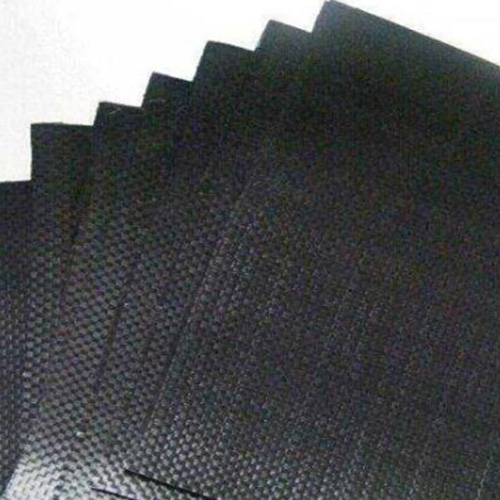

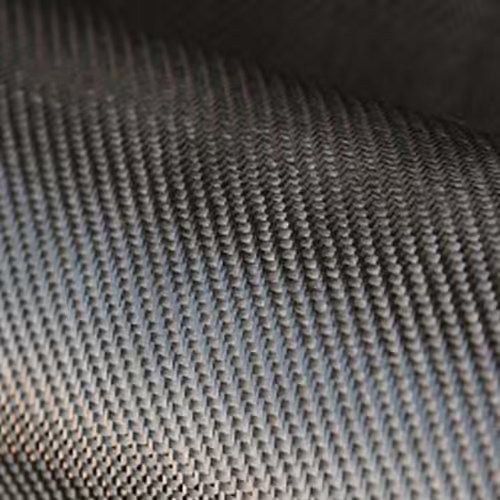

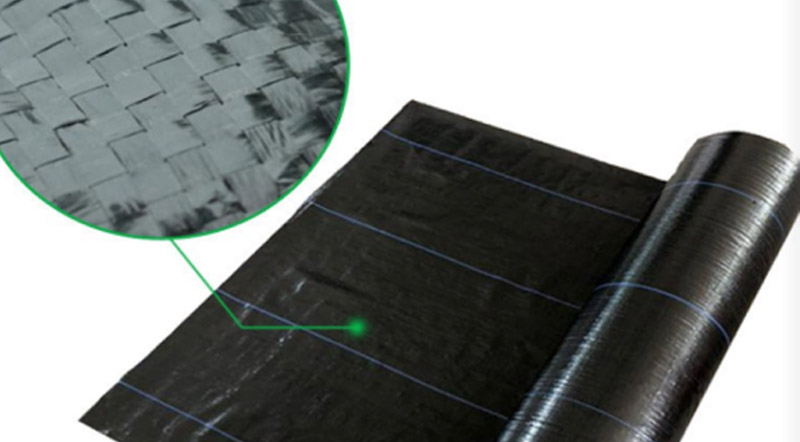

Woven geotextile is made from woven plastic filaments, offering very high tensile strength. It is primarily used for soil reinforcement in civil engineering to enhance stability. Its key function is to separate different soil layers, preventing material mixing. Additionally, its regular pore structure provides excellent drainage.

1. High strength: Woven geotextiles are made of high-strength industrial polypropylene, polyester, nylon and other synthetic fibers as raw materials, and are woven through a regular interwoven structure to further enhance the overall bearing capacity.

2. Durability: The synthetic fiber material of Woven Geotextile is stable and not easy to degenerate, decompose or weather, ensuring that the original characteristics are maintained for a long time.

3. Corrosion resistance: Woven Geotextile are usually acid-resistant, alkali-resistant, insect-resistant and mold-resistant, and can adapt to various complex environments.

4. Water permeability: The structural pores of Woven Geotextile are controllable, providing a certain degree of water permeability to meet engineering needs.

5. Convenient storage and transportation: Woven Geotextile are lightweight and can be packaged on demand, and the transportation, storage and construction processes are simple and efficient.

Product Parameters

| Model NO. | Woven geotextile | Color | Customizable |

| Certification | CE ISO | Feature | High strength, low elongation, drainage |

| Material | pp/pet/pe | Kind | woven |

| Width | 1m-6m (as Customrized) | Length | 100-600m or Customized |

| Weight | 70-800GSM(as Customrized) | Standard | ASTM or customer requirements |

| Geotextile Type | Woven Geotextiles | Transport Package | Inner Pipe + Outside Woven Bag or Film |

| Origin | China | Trademark | EcoGeo |

Product Feature

1.High strength: Due to its woven structure, it has high tensile strength and modulus in both the warp and weft directions (i.e., it is not easily stretched), enabling it to withstand enormous loads.

2.Excellent mechanical properties: stable structure, effective load distribution, and reduced uneven settlement.

3.Uniform porosity: Its pores are regular and continuous, and their main function is drainage and water conduction, rather than backfiltering (preventing soil erosion).

4.Durability: Resistant to chemical corrosion, insect damage, and ageing, with a longer service life.

4.Durability: Resistant to chemical corrosion, insect damage, and ageing, with a longer service life.

Product Details

Durability: Resistant to chemical corrosion, insect damage, and ageing, with a long service life.

Good mechanical properties

Uniform porosity

Application Scenarios

Transport infrastructure such as roads, railways and airports

Water engineering (dams, riverbanks, sea walls)

Environmental protection projects (landfills, mine tailings ponds)

Other applications (geotextile bags/geotextile Geotextile Tubes, agriculture and aquaculture)

Landscaping & Agriculture:For soil stabilization, drainage, and weed control.

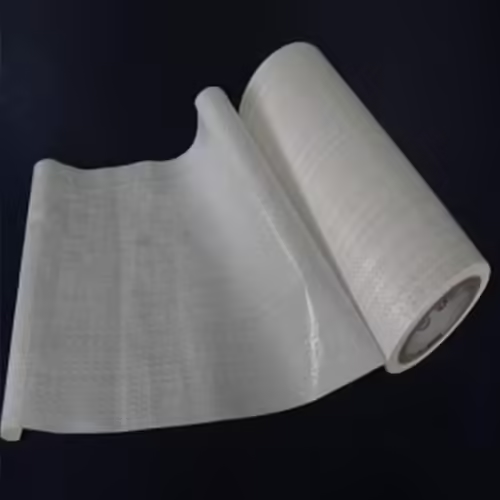

Packaging and delivery

Packaging unit: Rolled (width and length of each roll can be customized according to customer requirements)

Packaging method: plastic film, plastic woven bags, or packaging designed by the customer.

Packaging method: plastic film, plastic woven bags, or packaging designed by the customer.

Perguntas frequentes

How do I choose the right woven geotextile for my project?

It is essential to adhere to the technical specifications provided by the engineering designer. Do not make selections based solely on personal preference or price. The designer will calculate the minimum strength requirements based on the purpose of the project (reinforcement or separation), load size, foundation conditions, and other factors.

How can you easily determine the quality of woven geotextiles?

Can woven geotextiles be spliced? How are they spliced?

Related products

We focus on

environmental protection

Environmental protection concept to create a green future

We are committed to the field of environmental protection, and one way to achieve sustainable development in the geosynthetics industry is to use recyclable or renewable materials in the production process. This can reduce dependence on limited resources and help conserve energy and reduce greenhouse gas emissions. Additionally, companies can implement efficient production processes to minimize waste and optimize resource utilization.

Our product advantages

High Performance and Reliability

All our products are engineered for superior mechanical strength, chemical resistance, and long-term durability—ensuring consistent performance even in the most demanding environmental and structural conditions.

Cost-Effective and Efficient Solutions

Through advanced manufacturing and material optimization, our products deliver exceptional value by reducing installation time, minimizing maintenance, and extending the lifespan of infrastructure systems.

Environmentally Responsible Design

We prioritize sustainability by using recyclable materials, reducing construction waste, and supporting eco-friendly engineering practices that align with global environmental standards.

Perguntas frequentes

Who are we?

Which markets have our products reached?

How do we ensure product quality?

What is the lifespan of the geomembrane?

What are the specifications of the geomembranes?

Are our geomembranes suitable for special environments?

What delivery terms and payment methods do we offer?

Can we provide samples?

Contate-nos

Let’s Build Something Stronger, Smarter, and Greener