Оглавление

Введение

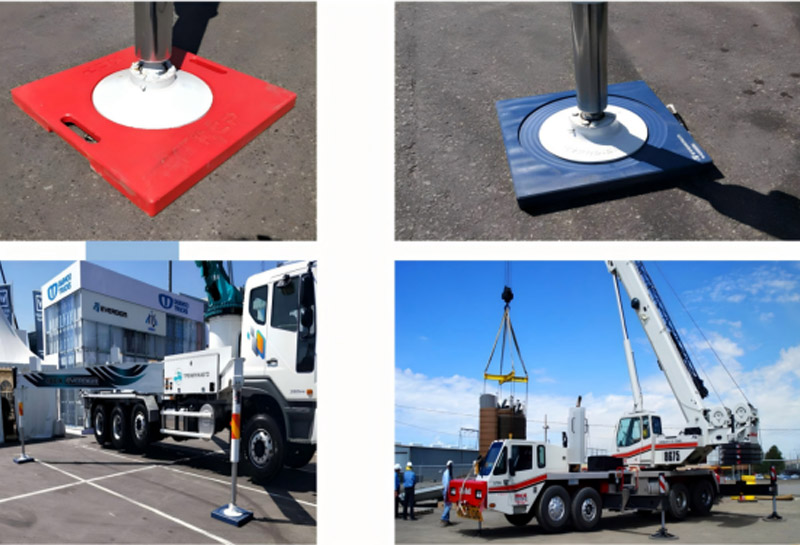

Infrastructure projects—whether building bridges, highways, tunnels, or utility structures—require stability, safety, and efficiency on job sites. Among the many tools that enable heavy equipment to perform safely, outrigger pads play a critical role. These engineered support systems provide the solid foundation needed for cranes, aerial lifts, and other machinery when operating on variable ground conditions.

At EcoGeo Material, we are dedicated to supplying advanced geosynthetic and support solutions for civil engineering, water management, and environmental protection projects worldwide. Our expertise extends to materials that improve ground stability and equipment performance, aligning perfectly with the needs of infrastructure development where outrigger pads are indispensable.

Почему outrigger pads are essential for infrastructure projects

Infrastructure projects often involve heavy lifting and equipment deployment on uneven or unstable soil. Outrigger pads distribute the load from machinery outriggers over a wider surface area, reducing ground pressure and preventing equipment from sinking or tipping.

Without proper pads, the risk of accidents increases significantly. According to industry safety reports, equipment instability is among the top five causes of crane-related incidents on construction sites. Incorporating outrigger mats minimizes these risks and ensures smoother project execution.

Applications of Outrigger mats in bridge and road construction

Bridge and road projects frequently demand cranes and drilling rigs operating on soil that has been recently excavated or compacted. Outrigger pads provide the necessary load-bearing support for these machines, preventing ground collapse and maintaining alignment.

For example, during road widening or elevated highway projects, pads allow equipment to operate on embankments and soft shoulders without compromising stability. This is crucial for meeting both safety regulations and project timelines.

Ground-bearing challenges and outrigger pad solutions

Different soil types pose unique challenges in infrastructure work. Sandy soils, wet ground, or reclaimed land can create unstable surfaces for heavy machinery. Outrigger pads offer tailored solutions by enlarging the bearing footprint and evenly distributing pressure.

Table: Comparing Ground Conditions and Outrigger Pad Performance

| Ground Condition | Risk Without Pads | Benefits of Outrigger Pads |

|---|---|---|

| Soft clay or wet soil | Machinery sinking or tilting | Stabilized support and load balance |

| Sandy terrain | Uneven pressure, outrigger damage | A wider footprint prevents shifting |

| Compacted gravel | High point loads | Even load distribution, longer pad life |

| Reclaimed land | Settlement under heavy loads | Reduced ground compaction, safer lifts |

This adaptability makes outrigger pads not only safety equipment but also efficiency tools, enabling construction teams to operate machinery in otherwise challenging conditions.

Regulations and standards for outrigger pads in infrastructure projects

Many regions and industry bodies have established safety requirements regarding outrigger pad usage. Standards emphasize ground stability assessments and proper load distribution before heavy lifting operations. Failing to use adequate outrigger mats may result in non-compliance, project delays, or penalties.

By following recognized guidelines, project managers ensure both legal compliance and worker safety. Using high-quality pads also demonstrates a commitment to best practices in infrastructure development.

How Outrigger mats improve project efficiency and cost control

Beyond safety, outrigger pads have a direct impact on cost efficiency. Stable equipment reduces downtime caused by accidents, soil repairs, or equipment repositioning. Fewer incidents mean fewer delays, helping contractors deliver projects on schedule.

Moreover, pads minimize ground damage, reducing the need for expensive site restoration after equipment removal. This cost-saving factor is particularly valuable in large-scale public infrastructure projects where budgets and deadlines are tightly controlled.

Заключение

In infrastructure projects, the reliability of heavy machinery directly impacts safety and productivity, making outrigger pads indispensable. From stabilizing cranes at bridge sites to ensuring safe operations on reclaimed land, outrigger pads protect workers, equipment, and investments. At Материал EcoGeo, we understand that support systems play a critical role in successful infrastructure development. If you aim for your project to meet the highest standards of safety and efficiency, integrate outrigger pads into every stage of planning and execution.

Часто задаваемые вопросы

What materials are outrigger pads typically made from?

They are usually made from engineered composites or high-density polymers designed for durability and strength in demanding environments.

Can outrigger pads be reused across multiple projects?

Yes. High-quality outrigger mats are designed for long-term use, provided they are inspected regularly and maintained properly.

How do I choose the right outrigger pad size for my equipment?

The correct size depends on the equipment’s load, outrigger dimensions, and ground conditions. Consulting load charts and manufacturer recommendations is essential.

Are outrigger pads required by safety regulations?

In many cases, yes. Industry standards and regulations often mandate the use of adequate load distribution systems when using cranes and other heavy equipment.