Table of Contents

Introduction

Have you ever faced the challenge of moving heavy equipment across soft ground, preventing damage to delicate landscapes, or creating temporary access roads in challenging conditions? If so, you understand the headaches that come with compromised surfaces. This is precisely where ground protection matting steps in, offering a robust and reliable solution. Far more than just a piece of plastic, ground protection matting is an essential tool for safeguarding surfaces, ensuring safety, and enhancing efficiency on a multitude of projects. In this comprehensive guide, we’ll explore five brilliant uses for ground protection matting, highlighting its invaluable role across diverse applications and demonstrating why it’s a wise investment for anyone looking to protect their ground assets.

What is Ground Protection Matting?

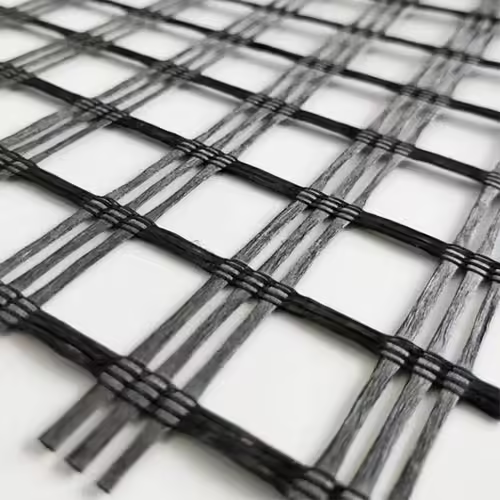

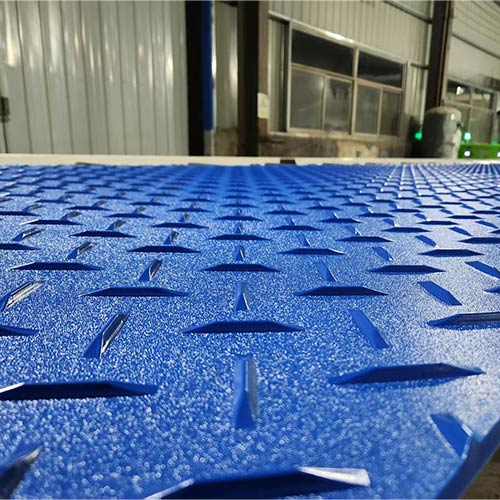

Before we delve into its applications, let’s briefly define what ground protection matting is. Typically made from high-density polyethylene (HDPE) or other durable composite materials, ground protection matting refers to robust, interlocking panels designed to distribute weight evenly over a surface. This prevents ruts, compaction, and general damage to the underlying ground, whether it’s grass, soil, or even sensitive paved areas. These mats are engineered to withstand significant loads, resist chemicals, and endure extreme weather conditions, making them an ideal solution for temporary access and surface preservation. Their lightweight yet incredibly strong nature makes them easy to deploy and remove, providing a flexible solution for a variety of needs.

5 Brilliant Uses for Ground Protection Matting

Ground protection matting offers an array of benefits across numerous industries. Its ability to provide stable surfaces and protect the underlying ground makes it indispensable.

NO 1. Temporary Access Roads and Work Platforms

One of the most common and vital uses for ground protection matting is the creation of temporary access roads and work platforms. On construction sites, especially those in rural or undeveloped areas, establishing stable pathways for heavy machinery like excavators, cranes, and trucks is crucial. Without proper ground protection matting, these vehicles can easily get stuck in mud, create deep ruts, and damage the terrain, leading to costly delays and environmental remediation. Ground protection matting provides a firm, reliable surface that supports heavy loads, ensuring uninterrupted workflow and preventing equipment from sinking.

Furthermore, these mats are invaluable for creating temporary work platforms around construction areas, offering a stable and safe environment for workers and equipment. This is particularly important when working on uneven or soft ground, where stability is paramount for operational safety and efficiency. The interlocking design of ground protection matting allows for quick installation and removal, making it a flexible solution for projects with evolving site layouts.

NO 2. Protecting Landscapes and Sensitive Areas

Another brilliant application of ground protection matting is in safeguarding delicate landscapes and sensitive environmental areas. Imagine a major event being set up on a pristine golf course, or construction work needing to traverse a meticulously maintained park. Without adequate protection, heavy foot traffic, vehicles, and equipment can quickly cause irreparable damage to turf, leading to compaction, erosion, and long-term restoration costs.

Ground protection matting acts as a protective barrier, dispersing the weight and preventing direct contact with the ground. This preserves grass, prevents soil compaction, and minimizes disruption to sensitive ecosystems. It’s widely used in events management, landscaping projects, and any situation where maintaining the integrity of natural or cultivated ground is a priority. This minimizes the environmental footprint of projects and helps maintain the aesthetic value of the area.

NO 3. Utility and Pipeline Installations

Utility and pipeline projects often involve digging trenches and transporting heavy pipes and equipment across various terrains, from urban streets to remote fields. These operations require continuous access for vehicles and machinery, and the ground can quickly become churned up and impassable. Ground protection matting provides essential support, creating stable pathways over disturbed ground, protecting existing infrastructure, and ensuring continuous access for workers and equipment.

In urban settings, ground protection matting can be used to protect sidewalks, driveways, and underground utilities from the weight of heavy machinery. In rural areas, it helps to prevent the formation of deep ruts and the destabilization of access routes. This application is crucial for maintaining project schedules and preventing damage to public or private property during critical utility installations.

NO 4. Event Management and Temporary Flooring

From large-scale music festivals and sporting events to outdoor exhibitions and temporary venues, ground protection matting plays a critical role in event management. These events often attract thousands of attendees and require the movement of heavy stage equipment, lighting rigs, and catering vehicles. Without proper ground protection, the sheer volume of foot traffic and vehicle movement can quickly turn grassy fields into muddy quagmires, ruining the event experience and damaging the venue.

Ground protection matting provides temporary flooring solutions that are safe, stable, and easy to clean. It can be laid over grass, gravel, or uneven surfaces to create walkways, parking areas, and stable platforms for tents and stages. This not only protects the underlying ground but also enhances the safety and comfort of attendees. After the event, the mats can be easily removed, leaving the venue in its original condition.

NO 5. Emergency Access and Disaster Relief

In times of emergency or natural disaster, rapid access for rescue vehicles, aid trucks, and heavy equipment is paramount. However, disaster-affected areas often have compromised or impassable roads, making quick response challenging. Ground protection matting offers a rapid deployment solution for creating temporary access routes over damaged terrain, flooded areas, or unstable ground.

It can be quickly laid to facilitate the movement of emergency services, provide access to isolated communities, or establish temporary staging areas for relief efforts. Its durability and ease of deployment make it an invaluable tool for humanitarian aid organizations, military operations, and emergency response teams, ensuring that critical supplies and personnel can reach those in need, even in the most challenging conditions.

Choosing the Right Ground Protection Matting

Selecting the appropriate ground protection matting depends on several factors, including the type of ground, the weight of the loads, and the duration of use. Below is a table outlining key considerations to help you make an informed decision.

| Feature | Description |

| Material Type | High-density polyethylene (HDPE) is common for its durability and chemical resistance. Other composites may offer specific advantages. |

| Weight Capacity | Ensure the matting can withstand the maximum load of vehicles and equipment it will support. |

| Surface Tread | Look for a tread pattern that provides adequate grip for vehicles and personnel, even in wet or muddy conditions. |

| Interlocking System | A robust interlocking system ensures stability, prevents mat separation, and creates a continuous, secure surface. |

| Dimensions & Weight | Consider the size and weight of individual mats for ease of transport, deployment, and storage. |

| Environmental Impact | Opt for reusable and recyclable options to minimize environmental footprint. |

| Temperature Range | Verify the mats can perform reliably in the expected temperature extremes of your project site. |

Conclusion

Ground protection matting is an indispensable asset across a diverse range of industries and applications. From facilitating heavy construction projects and safeguarding sensitive landscapes to enhancing event management and providing critical emergency access, its versatility and effectiveness are undeniable. By providing a stable, protective layer, ground protection matting not only prevents costly damage to underlying surfaces but also significantly improves safety and operational efficiency. The benefits of investing in high-quality ground protection matting far outweigh the potential costs of ground remediation, project delays, and equipment damage.

At EcoGeo Material, we understand the critical role that robust geosynthetics play in ensuring project success and environmental responsibility. We are proud to contribute to industries that require reliable ground protection solutions. If you’re looking for durable and effective ground protection matting solutions, we encourage you to contact us today to explore our range of products and discover how we can help safeguard your projects and investments.

FAQ

How heavy can ground protection matting typically support?

The weight capacity of ground protection matting varies significantly depending on the material, thickness, and design. Many heavy-duty ground protection mats are designed to support loads ranging from 60 tons to over 120 tons per square meter, making them suitable for most construction vehicles and equipment.

Is ground protection matting reusable?

Yes, one of the significant advantages of ground protection matting, especially those made from high-density polyethylene (HDPE), is their reusability. They are designed for repeated deployment and removal, offering a cost-effective and environmentally friendly solution over multiple projects. Proper cleaning and storage after each use will extend their lifespan.

Can ground protection matting be used on uneven terrain?

Ground protection matting can be used on moderately uneven terrain, as their flexible nature allows them to conform somewhat to the contours of the ground. However, for extremely uneven or sloped surfaces, additional ground preparation might be necessary to ensure stability and effectiveness. The interlocking systems help to create a more stable surface even on slightly irregular ground.

How is ground protection matting installed and removed?

Ground protection matting is designed for relatively easy installation and removal. Individual mats are typically lightweight enough to be handled by one or two people and feature interlocking connectors that allow them to be quickly linked together to form a continuous surface. Removal is just as straightforward, allowing for efficient project turnaround.

What are the environmental benefits of using ground protection matting?

Using ground protection matting offers several environmental benefits. It prevents soil compaction and erosion, preserves vegetation, and minimizes the need for extensive ground remediation after project completion. Additionally, many ground protection mats are made from recycled materials and are themselves recyclable at the end of their long service life, reducing waste.