Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61576267991871

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

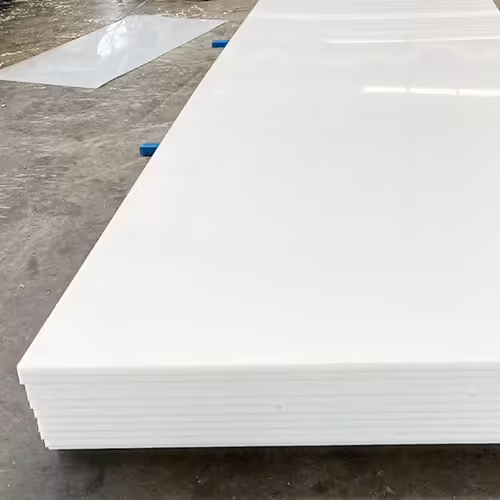

Ever wondered which material can endure heavy wear, resist harsh chemicals, and still be easy to work with? Enter UHMWPE sheets—a game-changer in engineering. At EcoGeo Material, we specialize in high-quality geosynthetic solutions, including UHMWPE sheets, crafted for industries like water management, environmental protection, and more. Let’s dive into why these sheets are so impactful and how they can elevate your projects. Ready? Let’s go!

What Makes UHMWPE Sheets Stand Out?

Unmatched Durability of UHMWPE Sheets

When it comes to toughness, UHMW-PE sheets are in a league of their own. Ultra-High Molecular Weight Polyethylene (UHMWPE) boasts an incredibly high molecular weight, making it one of the most durable thermoplastics available. According to a study by the Journal of Materials Science, UHMWPE has a tensile strength of up to 40 MPa and exceptional impact resistance, outperforming many metals and plastics. This durability translates to a material that can handle heavy loads, abrasive environments, and extreme weather without cracking or degrading.

For you, this means UHMWPE sheets are perfect for demanding applications like landfill liners, conveyor systems, or marine fendering. Whether it’s a rugged mining site or a busy wastewater treatment facility, these sheets keep performing, saving you maintenance costs and headaches.

Superior Chemical Resistance for UHMW-PE Sheets

Worried about corrosion or chemical damage? UHMW-PE sheets laugh in the face of harsh substances. They resist acids, alkalis, and organic solvents, making them ideal for environments like wastewater treatment plants or chemical storage facilities. A report from the American Society for Testing and Materials (ASTM) highlights UHMWPE’s ability to withstand prolonged exposure to chemicals without losing structural integrity.

This chemical resistance makes UHMWPE sheets a go-to for industries where exposure to corrosive materials is a daily reality. You can trust these sheets to protect your infrastructure, ensuring long-term reliability.

Low Friction and High Wear Resistance

Imagine a material that reduces friction so effectively it keeps machinery running smoothly for years. That’s exactly what UHMW-PE sheets deliver. Their low coefficient of friction—around 0.15, as per Engineering Plastics Handbook—makes them ideal for applications like conveyor belts, chute liners, and sliding surfaces. This low friction also means less wear and tear, extending the lifespan of both the sheets and the equipment they interact with.

For your projects, this translates to smoother operations and fewer replacements. Whether you’re lining a hopper or designing a low-maintenance conveyor system, UHMWPE sheets keep things moving efficiently.

Applications of UHMWPE Sheets in Real-World Projects

Versatility Across Industries

One of the biggest selling points of UHMWPE sheets is their versatility. From environmental protection to aquaculture, these sheets adapt to a wide range of applications. In water management, they’re used as geomembranes to prevent seepage in reservoirs and canals. In landscaping, they stabilize slopes and promote greening. Even in mining, UHMWPE sheets are employed for equipment linings and site restoration, thanks to their durability and flexibility.

You name the industry, and UHMW-PE sheets have a role to play. Their ability to perform under diverse conditions makes them a favorite among engineers and project managers worldwide.

Environmental Benefits of UHMWPE Sheets

Sustainability matters, and UHMWPE sheets deliver on that front too. Their long lifespan reduces the need for frequent replacements, cutting down on waste. Plus, they’re recyclable, aligning with eco-friendly project goals. In landfill applications, UHMWPE sheets act as impermeable barriers, preventing leachate from contaminating groundwater—a critical factor in environmental protection, as noted by the Environmental Protection Agency (EPA).

Choosing UHMWPE sheets means you’re not just investing in durability but also contributing to a greener planet. It’s a win-win for your project and the environment.

Comparing UHMWPE Sheets to Other Materials

To give you a clearer picture, let’s compare UHMWPE sheets to other common materials. The table below highlights key properties, showing why UHMWPE often comes out on top.

| Material | Tensile Strength (MPa) | Chemical Resistance | Friction Coefficient | Impact Resistance | Typical Applications |

|---|---|---|---|---|---|

| UHMWPE Sheet | 40 | Excellent | 0.15 | High | Liners, geomembranes, conveyors |

| HDPE | 30 | Good | 0.20 | Moderate | Pipes, containers |

| Steel | 400 | Poor | 0.60 | High | Structural components |

| PVC | 50 | Moderate | 0.40 | Low | Piping, signage |

| PTFE | 25 | Excellent | 0.10 | Low | Seals, gaskets |

As you can see, UHMWPE sheets offer a unique balance of strength, chemical resistance, and low friction, making them a versatile choice for projects where other materials might fall short.

How UHMWPE Sheets Enhance Project Efficiency

Ease of Installation and Customization

One of the best things about UHMWPE sheets? They’re incredibly easy to work with. Lightweight yet strong, these sheets can be cut, shaped, and installed with minimal effort. According to Plastics Engineering Magazine, UHMWPE’s machinability allows for precise customization, whether you need specific dimensions for a geomembrane or tailored linings for industrial equipment.

This ease of use saves you time and labor costs, letting you focus on getting your project up and running. Plus, their flexibility means you can adapt them to complex designs without sacrificing performance.

Cost-Effective Long-Term Solution

While upfront costs are always a consideration, UHMW-PE sheets shine in the long run. Their durability and low maintenance needs mean fewer repairs and replacements. A study by Industrial Materials Journal found that UHMWPE linings in conveyor systems lasted up to 5 times longer than traditional materials like steel or rubber.

For you, this means a lower total cost of ownership. Investing in UHMWPE sheets is like putting money in the bank—reliable performance that pays off over time.

Conclusion

So, why should you choose UHMWPE sheets for your next project? They’re durable, chemically resistant, low-friction, and versatile enough to tackle everything from environmental protection to industrial applications. At our factory, we’re passionate about delivering top-tier geosynthetic solutions, including UHMW-PE sheets, to help you unlock the full potential of your projects. Whether you’re managing a landfill, stabilizing a slope, or optimizing a conveyor system, these sheets deliver unmatched performance.

Ready to take your project to the next level? Contact us today to explore how UHMWPE sheets can make a difference. Let’s build something durable, sustainable, and efficient together!

FAQ

What are UHMWPE sheets used for?

UHMW-PE sheets are used in a wide range of applications, including geomembranes for water management, liners for conveyors and chutes, and barriers in landfills. Their durability and chemical resistance make them ideal for industries like environmental protection, mining, and aquaculture.

How durable are UHMW-PE sheets compared to other plastics?

Incredibly durable! UHMW-PE sheets have a tensile strength of around 40 MPa and outperform materials like HDPE and PVC in impact resistance and wear, according to Journal of Materials Science data. They’re built to last in tough conditions.

Can UHMW-PE sheets withstand harsh chemicals?

Absolutely. UHMW-PE sheets resist acids, alkalis, and solvents, making them perfect for wastewater treatment or chemical storage, as confirmed by ASTM standards.

Are UHMW-PE sheets environmentally friendly?

Yes! Their long lifespan reduces waste, and they’re recyclable. In applications like landfill liners, UHMW-PE sheets prevent environmental contamination, aligning with EPA guidelines.

How easy is it to install UHMW-PE sheets?

Super easy! UHMW-PE sheets are lightweight and machinable, allowing for quick cutting and shaping to fit your project, as noted in Plastics Engineering Magazine. This saves time and labor costs.