Welcome to My Blog!

Before we dive into the content, I’d love for you to join me on my social media platforms where I share more insights, engage with the community, and post updates. Here’s how you can connect with me:

Facebook:https://www.facebook.com/profile.php?id=61576267991871

Now, let’s get started on our journey together. I hope you find the content here insightful, engaging, and valuable.

Table of Contents

Introduction

Have you ever wondered how modern construction projects can last even in the most demanding environments? The secret often lies with a quiet hero: geotextile cloth. As a leading manufacturer of geosynthetics, we’ve seen firsthand how this versatile material has transformed projects in areas such as water management and environmental protection. It’s the backbone of long-lasting, sustainable infrastructure.

In this blog, we’ll dive into the need for geosynthetics and explore their benefits and applications. You’ll get a clear understanding of why they’re a must-have material for creating stronger, smarter, and greener buildings. Let’s get started!

What Is Geotextile Cloth and Why Does It Matter?

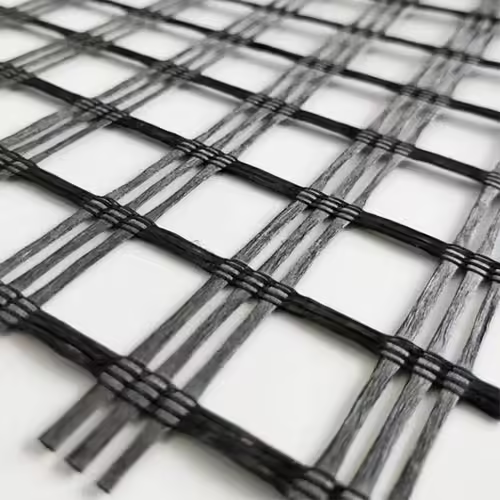

Geotextile cloth is a synthetic textile designed specifically for civil engineering and environmental applications. Made from durable materials like polyester or polypropylene, it comes in two main forms: woven and nonwoven. Each type serves unique purposes, from reinforcing soil to filtering water, making it a versatile solution for a wide range of projects.

Why does this matter to you? Because geotextile cloth solves real-world problems. It stabilizes soil to prevent erosion, extends the lifespan of infrastructure, and reduces maintenance costs. According to a 2023 study by the Geosynthetic Institute, projects incorporating geotextiles saw a 30% increase in structural longevity compared to those without. Whether you’re a contractor, engineer, or property owner, this material offers a cost-effective way to ensure your project stands the test of time.

Woven vs. Nonwoven Geotextile: What’s the Difference?

- Woven Geotextile Cloth: Think of woven geotextiles as the heavy-duty workhorse. It’s tightly interlaced for maximum strength, making it ideal for applications like road stabilization or load-bearing foundations. Its high tensile strength ensures it can handle significant stress, perfect for projects requiring reinforcement.

- Nonwoven Geotextile Cloth: This type is softer and more flexible, resembling felt. It excels in filtration and drainage tasks, such as preventing soil clogging in drainage systems or protecting liners in landfills. Its permeability makes it a go-to for environmental projects.

Choosing the right type depends on your project’s needs. For example, a highway project might lean on woven geotextile cloth for reinforcement, while a wastewater treatment facility might opt for nonwoven for filtration. Understanding these differences empowers you to make informed decisions.

Key Benefits of Using Geotextile Cloth in Construction

Why should you incorporate geotextile into your next project? The benefits are hard to ignore. Here’s a breakdown of why this material is a must-have:

1. Soil Stabilization and Erosion Control

Geotextile cloth acts like a shield for soil, preventing erosion caused by wind, water, or heavy traffic. By distributing loads evenly, it reduces soil displacement, ensuring structures like roads, embankments, and slopes remain stable. A 2022 report by the International Erosion Control Association noted that geotextiles reduced erosion by up to 85% in high-risk areas like riverbanks and coastal zones.

2. Enhanced Drainage and Filtration

Nonwoven geotextile cloth shines in drainage systems. It allows water to pass through while trapping fine particles, preventing clogs and maintaining efficient water flow. This is critical for projects like landfills or aquaculture ponds, where water management is key.

3. Increased Durability of Infrastructure

By reinforcing soil and separating layers, geotextiles extends the lifespan of roads, retaining walls, and other structures. It reduces the need for frequent repairs, saving you time and resources in the long run.

4. Environmental Sustainability

Geotextile cloth supports eco-friendly construction. It minimizes the need for natural resources like gravel and reduces land disturbance. Plus, it’s often made from recyclable materials, aligning with sustainable building practices.

5. Versatility Across Applications

From landscaping to mining restoration, geotextile cloth adapts to countless scenarios. Its ability to perform in diverse environments—wet, dry, acidic, or alkaline—makes it a universal solution for modern construction challenges.

Applications of Geotextile Cloth: Where It Shines

Geotextile cloth isn’t just a one-trick pony—it’s a multi-tool for construction and environmental projects. Here are some of its standout applications:

Road and Pavement Construction

Building a road that lasts? Geotextile cloth is your ally. Placed between the subgrade and aggregate layers, it prevents mixing, ensuring a stable base. This reduces potholes and cracking, even under heavy traffic. The American Society of Civil Engineers (ASCE) estimates that geotextiles can extend pavement life by up to 50%.

Landfills and Environmental Protection

In landfills, geotextiles acts as a protective barrier, preventing leaks and contamination. Nonwoven geotextile cloth is often used to filter leachate, ensuring harmful substances don’t seep into groundwater. This is critical for meeting stringent environmental regulations.

Water Management and Aquaculture

For dams, canals, and aquaculture ponds, geotextile cloth provides impermeable linings or filtration layers. It prevents soil erosion in water-heavy environments and ensures clean water circulation in fish farms.

Landscaping and Slope Greening

Want a lush, stable hillside? Geotextile cloth holds soil in place, promoting vegetation growth while preventing runoff. It’s a favorite for creating sustainable, low-maintenance landscapes.

Mining and Site Restoration

In mining, geotextiles supports site rehabilitation by stabilizing soil and controlling sediment. It’s also used in tailings management to prevent environmental damage, ensuring safer, cleaner operations.

Comparing Geotextile Cloth Types and Specifications

To help you choose the right geotextiles for your project, here’s a handy comparison table summarizing key characteristics:

| Type | Material | Key Features | Best Applications |

|---|---|---|---|

| Woven Geotextile Cloth | Polypropylene, Polyester | High tensile strength, low elongation | Road stabilization, embankments, retaining walls |

| Nonwoven Geotextile Cloth | Polypropylene, Polyester | High permeability, flexible, excellent filtration | Drainage systems, landfills, erosion control |

| Needle-Punched Nonwoven | Polyester | Thicker, better cushioning | Protection layers, landscaping |

| Heat-Bonded Nonwoven | Polypropylene | Smoother surface, high filtration efficiency | Filtration in wastewater treatment |

This table provides a snapshot of how different geotextile cloth types suit specific needs. Always consult with your supplier to ensure the material meets your project’s technical requirements, such as tensile strength or permeability.

How to Choose the Right Geotextile Cloth for Your Project

Selecting the perfect geotextile cloth can feel overwhelming, but it doesn’t have to be. Here’s a step-by-step guide to make the process easier:

Step 1: Define Your Project Goals

Are you stabilizing a road, preventing erosion, or improving drainage? Your project’s primary function will guide whether you need woven or nonwoven geotextile.

Step 2: Assess Site Conditions

Consider the environment—soil type, water exposure, and load requirements. For example, sandy soils may need nonwoven geotextile for filtration, while clay-heavy sites might benefit from woven for reinforcement.

Step 3: Check Specifications

Look at technical specs like tensile strength, permeability, and UV resistance. These ensure the geotextile cloth can withstand your project’s demands.

Step 4: Consult Experts

Work with a trusted manufacturer to confirm your choice. Our team, with years of experience in geosynthetic solutions, can help you select the ideal product for your specific needs.

Step 5: Plan Installation

Proper installation is key to maximizing geotextile cloth performance. Ensure overlaps, secure anchoring, and compatibility with other materials like geomembranes.

Installation Tips for Geotextile Cloth Success

Installing geotextile cloth correctly is just as important as choosing the right type. Here are some pro tips to ensure success:

- Prepare the Site: Clear debris and level the ground to create a smooth surface for the geotextile.

- Overlap Properly: Overlap seams by at least 12–18 inches to prevent gaps that could compromise performance.

- Secure the Cloth: Use stakes or weights to hold the geotextile in place, especially in windy conditions.

- Cover Promptly: Protect the cloth from UV exposure by covering it with soil or aggregate soon after installation.

- Inspect Regularly: Check for tears or shifts during installation to avoid costly rework.

Following these steps ensures your geotextile cloth performs at its best, delivering long-term stability and protection.

Why Geotextile Cloth Is a Smart Investment for the Future

Investing in geotextile isn’t just about solving today’s problems—it’s about building for tomorrow. Its durability reduces maintenance costs, while its eco-friendly properties align with growing demands for sustainable construction. According to a 2024 industry report by MarketsandMarkets, the global geotextile market is expected to grow by 6.5% annually through 2030, driven by increasing infrastructure projects and environmental regulations. By incorporating geotextile now, you’re staying ahead of the curve and ensuring your projects meet future standards.

Conclusion

So, why use geotextile cloth now? Because it’s the smart, sustainable, and cost-effective choice for building stronger infrastructure. From stabilizing roads to protecting the environment, this versatile material delivers unmatched performance across countless applications. As a dedicated manufacturer of geosynthetic materials, we’re passionate about helping you achieve project success with high-quality geotextile cloth tailored to your needs. Whether you’re tackling a small landscaping job or a massive municipal project, we’ve got the expertise and products to make it happen.

Ready to take your project to the next level? Contact us today to explore how geotextile cloth can transform your work. Let’s build stronger, together!

FAQ

What is geotextile cloth made of?

Geotextile is typically made from synthetic materials like polypropylene or polyester. These materials are chosen for their durability, resistance to environmental factors, and ability to perform in demanding conditions.

How does geotextile prevent erosion?

Geotextiles tabilizes soil by distributing loads and preventing displacement. It acts as a barrier against wind and water, holding soil in place while allowing water to pass through, reducing runoff and erosion.

Can geotextile be used in wet environments?

Absolutely! Geotextile is designed to perform in wet conditions, making it ideal for applications like drainage systems, aquaculture, and waterfront projects. Nonwoven types are especially effective for filtration in wet environments.

Is geotextile environmentally friendly?

Yes, geotextile supports sustainable construction. It reduces the need for natural resources, minimizes land disturbance, and is often made from recyclable materials, aligning with eco-friendly practices.

How do I know which geotextile is right for my project?

Start by defining your project’s needs—stabilization, filtration, or protection. Then, consider site conditions and consult with a supplier to match the geotextile’s specifications to your requirements.