Low-density polyethylene (LDPE) geomembrane has excellent environmental stress cracking resistance and excellent chemical corrosion resistance, and is widely used in construction, water conservancy, chemical industry, transportation, subway, garbage disposal, reservoir dam reinforcement, tunnel and other projects. The flexibility and price advantages of low-density polyethylene LDPE geomembrane are unmatched by high-density polyethylene (HDPE) geomembrane.

Product Parameters

| ModelNO. | LDPEGeomembrance | Certification | CE,ISO |

| Surface | Smooth | Application | Transportation Project, Hydraulic Project, Geotechnical Project, Environmental Project |

| Feature | Puncture Resistance, Impact Resistance, Tear Resistance | Material | LDPE |

| Feature | Black | Other Color | White、 Blue、 Green and etc,(Customizable) |

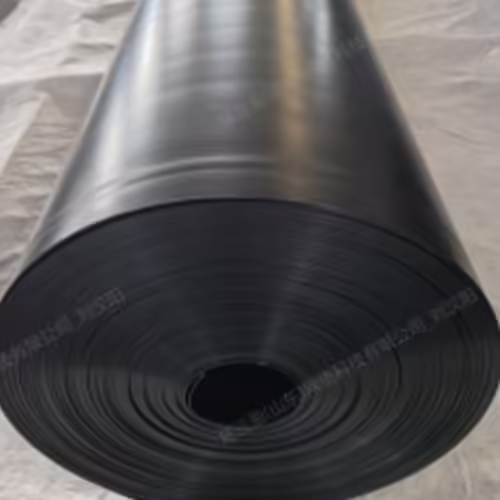

| Other Surface | Smooth /Textured | Length | 50m-400m(Customizable) |

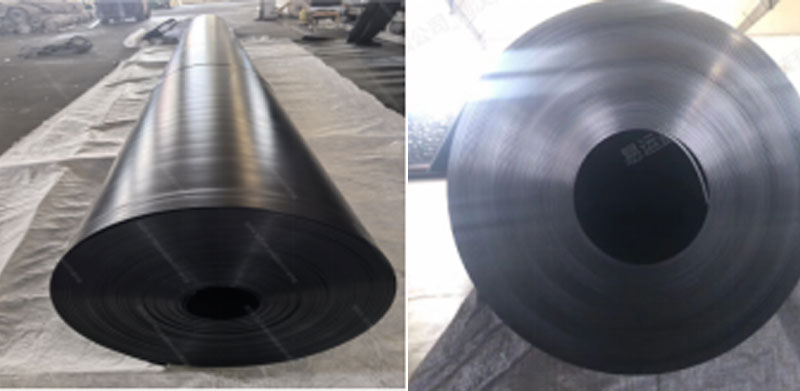

| Transport Package | Paper Roll +Woven Geotextile | Specification | 0.2mm-3.0mm |

| Trademark | EcoGeo | Origin | China |

| HS Code | 3920109090 | Production Capacity | 50000sqm Per Day,Depends on The Specification |

Product Usage Scenarios

Product highlights in detail

Low-density polyethylene (LDPE) geomembrane has excellent environmental stress cracking resistance and excellent chemical corrosion resistance, and is widely used in construction, water conservancy, chemical industry, transportation, subway, garbage disposal, reservoir dam reinforcement, tunnel and other projects. The flexibility and price advantages of low-density polyethylene LDPE geomembrane are unmatched by high-density polyethylene (HDPE) geomembrane.

1) Excellent flexibility and puncture resistance;

2) High impact strength;

3) Excellent low-temperature resistance;

4) Excellent resistance to environmental stress cracking

1) Excellent flexibility and puncture resistance;

2) High impact strength;

3) Excellent low-temperature resistance;

4) Excellent resistance to environmental stress cracking

Product advantages and details

1. Excellent Flexibility

LDPE geomembrane has high tensile mechanical properties. Its excellent elasticity and deformability make it well-suited to the expansion and contraction of the foundation surface, effectively overcoming uneven subgrade settlement.

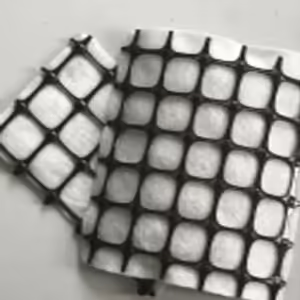

2. Dual-Surface Options

The smooth surface facilitates fluid flow and cleaning, while the rough surface enhances friction with the backfill. Both textures can be flexibly selected based on project requirements.

3. Strong Base Protection

Excellent tensile and bursting strength withstands the impact of mechanical paving and backfilling, while also resisting the risk of puncture during subsequent operations, providing a solid barrier for environmental protection and aquaculture waters.

4. Excellent resistance to environmental stress cracking and chemical attack.

5. Low permeability

Geomembrane contains no less than 94% pure polyethylene polymer and no more than 3% carbon black, antioxidants, and heat stabilizers.

LDPE geomembrane has high tensile mechanical properties. Its excellent elasticity and deformability make it well-suited to the expansion and contraction of the foundation surface, effectively overcoming uneven subgrade settlement.

2. Dual-Surface Options

The smooth surface facilitates fluid flow and cleaning, while the rough surface enhances friction with the backfill. Both textures can be flexibly selected based on project requirements.

3. Strong Base Protection

Excellent tensile and bursting strength withstands the impact of mechanical paving and backfilling, while also resisting the risk of puncture during subsequent operations, providing a solid barrier for environmental protection and aquaculture waters.

4. Excellent resistance to environmental stress cracking and chemical attack.

5. Low permeability

Geomembrane contains no less than 94% pure polyethylene polymer and no more than 3% carbon black, antioxidants, and heat stabilizers.

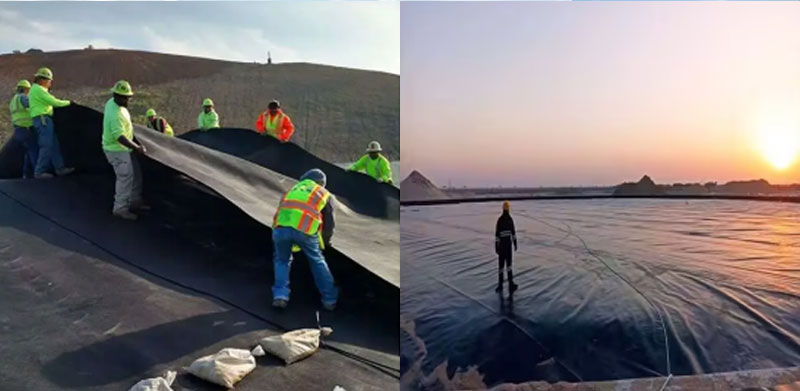

Product usage scenarios

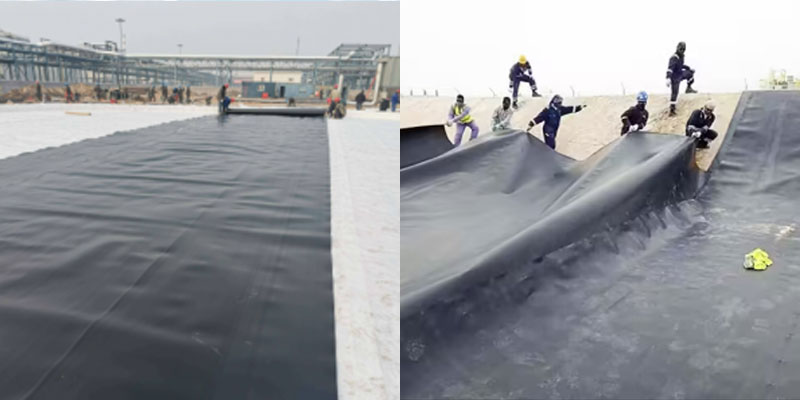

In pond projects, LDPE geomembrane acts as a continuous, impermeable "invisible pool bottom" that can completely block water infiltration and soil salt backflow, achieving long-term water retention and reducing water replenishment; the smooth membrane surface inhibits the accumulation of weeds and silt, reduces the frequency of dredging, and prevents the infiltration of exogenous pollutants, providing a stable and clean growth environment for fish and shrimp, thereby significantly increasing production and reducing operating costs.

In the biogas tank, geomembrane (LDPE) forms a fully enclosed anti-seepage barrier, which not only prevents the leakage of biogas liquid and pollutes the soil and groundwater, but also efficiently collects methane gas and increases the gas production rate; its excellent chemical corrosion resistance and puncture resistance can withstand the anaerobic fermentation environment for a long time, reduce maintenance costs, and achieve a win-win situation of environmental protection and energy efficiency.

In landfills, LDPE geomembrane serves as the core anti-seepage barrier, forming a composite liner system with GCL and drainage nets: the bottom main membrane and the upper leachate collection membrane provide dual barriers to leachate infiltration and harmful gas escape. Its chemical corrosion resistance, puncture resistance, and aging resistance ensure a safe lifespan of 10 years. Combined with the drainage system, leachate can be centrally treated and biogas can be recycled, achieving zero environmental pollution and resource reuse.

In highway and railway roadbeds, LDPE geomembranes serve as an integrated "waterproof + reinforcement" layer to block the infiltration of capillary water and rainwater, and prevent the base layer from softening, frost heaving and slurrying; at the same time, their high tensile strength is used to inhibit differential settlement, extend the life of asphalt pavement or sleepers, reduce the number of maintenance closures, and achieve cost reduction and efficiency improvement throughout the entire life cycle.

At the mine, LDPE geomembrane is laid at the bottom and slopes of tailings ponds, heap leaching sites, and spoil dumps, forming a chemical barrier that is resistant to strong acids and punctures, completely isolating heavy metal-containing leachate from the surrounding soil and groundwater. Combined with a drainage system, valuable solutions can be recycled, reducing environmental risks and increasing resource recovery rates. At the same time, its UV and aging resistance ensure long-term stable operation in extreme climates.

In water reservoir projects, LDPE geomembrane serves as an integral anti-seepage liner, which can completely block water leakage and underground saltwater intrusion, achieving long-term and efficient water storage. Its smooth surface inhibits the adhesion of algae and sediment, reducing dredging and maintenance. At the same time, its anti-UV and anti-aging properties ensure a service life of more than 10 years, significantly reducing water replenishment and operation and maintenance costs.

Packaging

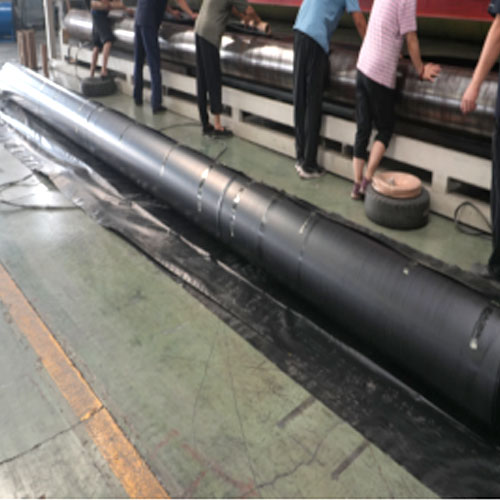

Production workshop

FAQ

What markets have we entered into with our LDPE geomembranes?

Our LDPE geomembranes are primarily sold domestically, with further exports to Southeast Asia, Eastern Europe, Africa, South Asia, East Asia, North America, South America, Oceania, Western Europe, Southern Europe, Central America, Northern Europe, and the Middle East.

How do we ensure product quality?

What is the service life of our LDPE geomembranes?

What are the specifications of our LDPE geomembranes?

Is our LDPE geomembrane suitable for special environments?

What delivery terms and payment methods do we offer?

Can we provide samples?

Related products

We focus on

environmental protection

Environmental protection concept to create a green future

We are committed to the field of environmental protection, and one way to achieve sustainable development in the geosynthetics industry is to use recyclable or renewable materials in the production process. This can reduce dependence on limited resources and help conserve energy and reduce greenhouse gas emissions. Additionally, companies can implement efficient production processes to minimize waste and optimize resource utilization.

Our product advantages

High Performance and Reliability

All our products are engineered for superior mechanical strength, chemical resistance, and long-term durability—ensuring consistent performance even in the most demanding environmental and structural conditions.

Cost-Effective and Efficient Solutions

Through advanced manufacturing and material optimization, our products deliver exceptional value by reducing installation time, minimizing maintenance, and extending the lifespan of infrastructure systems.

Environmentally Responsible Design

We prioritize sustainability by using recyclable materials, reducing construction waste, and supporting eco-friendly engineering practices that align with global environmental standards.

FAQ

Who are we?

Which markets have our products reached?

How do we ensure product quality?

What is the lifespan of the geomembrane?

What are the specifications of the geomembranes?

Are our geomembranes suitable for special environments?

What delivery terms and payment methods do we offer?

Can we provide samples?

Contact Us

Let’s Build Something Stronger, Smarter, and Greener