| Model NO. | Continuous Filament Geotextile | Color | Customizable |

| Certification | CE ISO | Feature | Corrosion Resistant, Oxidation Resistance, Wear Resistance |

| Material | pp/pet | Kind | Non-woven |

| Width | 2m-6m (as Customrized) | Length | 30m, 100m or Customized |

| Weight | 100-800GSM | Standard | ASTM or customer requirements |

| Geotextile Type | Non-Woven Geotextiles | Transport Package | Inner Pipe + Outside Woven Bag or Film |

| Origin | China | Trademark | EcoGeo |

Product Feature

2.Balanced permeability and filtration: Uniform pores between fibers enable efficient drainage while retaining soil particles to prevent loss, combining water seepage and filtration functions.

3.Strong environmental adaptability: Core materials (e.g., polyester filaments) feature excellent aging resistance, chemical inertness, and weatherability, maintaining long-term performance stability in complex soil, water, and climatic conditions.

4.Excellent structural integrity: The continuous filament structure, formed via processes like spunbonding and needle-punching, resists shedding or breakage, ensuring functional completeness during construction and use.

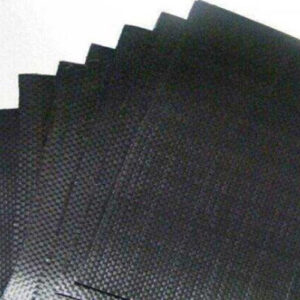

Detailed picture

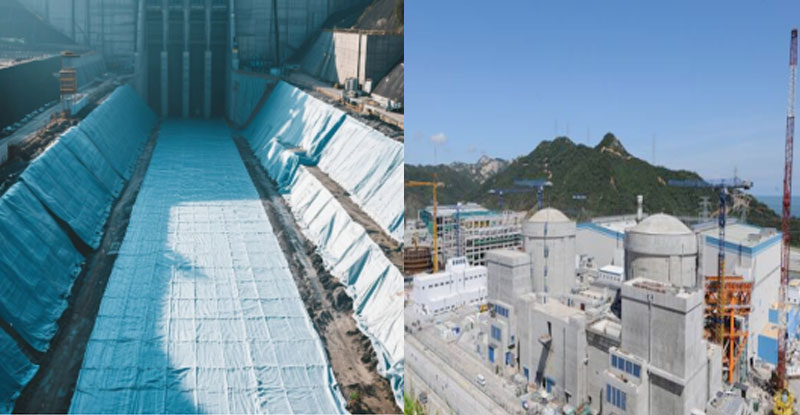

Application Diagram

Packaging and delivery

Packaging method: plastic film, plastic woven bags, or packaging designed by the customer.

FAQ

The core material of Continuous Filament Geotextile is polyester (PET) continuous filament, made from high-molecular-weight polymers. The fibres are formed through melt spinning and stretching into continuous long fibres, then processed into the final product via needle-punching or weaving techniques.

Key differences from staple fiber geotextile:

Fibre length: Filaments are continuous fibres (typically ≥100 mm in length), while short fibres are cut into short lengths (20–50 mm);

Performance: Long-strand geotextiles offer superior tensile strength, tear resistance, and abrasion resistance, making them suitable for high-strength engineering applications (e.g., highway subgrade reinforcement). Staple fiber geotextile are more cost-effective, have slightly better permeability, and are suitable for general waterproofing or filtration applications (e.g., agricultural water conservancy).